light industry

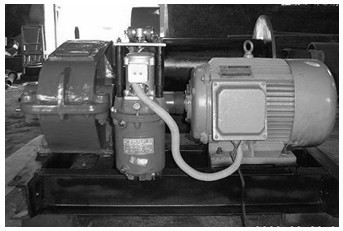

Application of ECF500 inverter in the windlass

2016-05-13

一、preface

Also called the hoist winch, by human or mechanical power driven drum winding rope to complete the work of traction device. Lifting, horizontal or inclined to pull the weight of the simple lifting machinery. Breaking up and electric two.

Electric hoist comprises a motor, coupling, brake, gear box and drum, common rack mounted. For lifting degree and large loading and unloading, busy working conditions, the requirements of good performance, especially to empty hook can quickly drop. To install in place or sensitive materials, to be able to decrease the speed of movement.

Hoister comprises, electric hoist, building hoist, minisize hoister's main products are: JM electronically controlled slow large tonnage hoist, JM electronically controlled slow winch, JK electronic high-speed hoister, JKL hand control fast humping windlass, 2JKL hand controlled double humping hoister, electric control control dual-purpose winch, JT speed winches etc., can only be used on the ground, by modifying the for the ship. It to motor as a driving force, the elastic coupling, three closed type gear reducer, jaw coupling driven drum, the electromagnetic brake. Winch products high versatility, compact structure, small volume, light weight, great, use convenient transfer, is widely used in construction, water conservancy, forestry, mining, port and other material lifting or flat drag, can also be used as a modern, electronically controlled automatic production line equipment.

二、The traditional control method of hoist

Hoist the work characteristics are: starting speed, torque, speed smooth, stable and accurate parking. The traditional control method is: the wound rotor asynchronous motor, through set electric ring and a carbon brush in the rotor circuit string into a plurality of resistance and access resistance by the contactor control to control the speed.

But there are some disadvantages:

(1) series resistance speed control, the speed change a jump like that between the gear reducer, a head sheave, a round, skip and skew bridge rail, in terms of acceleration, deceleration stage are subject to the impact of the role, easy damage of equipment, wire rope fatigue, resulting in large amount of maintenance, the maintenance costs increase.

(2) series resistance speed range is small, the skip rate was mutation, deceleration parking still has high speed, to the brake and the limit switch position adjustment precision of the high requirements, and prone to offside and off road accidents and affect production.

(3) series resistance speed, the skip starting and gear. Most of the electricity can be dissipated in the resistor; when the motor when the voltage drop and torque decreased slip increases, serious, skip car doesn't start, easy to produce accident.

(4) high energy consumption, low speed mechanical characteristics. Because speed is reduced through the outer rotor resistor energy consumption to achieve, and the speed is low, mechanical properties of the soft, consumption in electrical resistance in the proportion of energy more, extremely economical and grid voltage level of speed.

Schedule: comparison of rotor series resistance speed and variable frequency speed regulation

|

Serial number |

project |

Rotor series resistance speed regulation |

frequency control |

|

1 |

Plus, deceleration time |

Addition, deceleration time changes with the load, easy to produce deceleration section of speeding, over the volume and other issues. |

Addition, deceleration time does not change with the load, improve the production efficiency. |

|

2 |

Mechanical shock |

Plus, when the mechanical impact of the slowdown, the impact of large mechanical shock. |

Running smoothly, without mechanical shock |

|

3 |

Grid Impact |

The impact of the power grid is large, which is 3 to 5 times of the rated current, and the speed of the power grid is also great impact on the power grid. |

The output current is about 1.2 times of the rated current, and the output current is not output electric shock at constant velocity, deceleration and creep. |

|

4 |

Low speed crawl |

Crawling mainly by the brake control, unstable. |

Low speed crawling and stability, can be in the low speed and smooth operation of 0.1M/S. |

|

5 |

Energy system |

Energy saving, the resistance of the transfer of power consumption is very large. |

Energy saving is obvious, generally in 20% ~ 40% above. |

|

6 |

Brake wear |

Frequent brake, brake wear, dust. |

Brake wear, reduce dust, environmental good duty. |

三、ECF500 vector inverter winch control scheme

Yi chuang fei ECF500 vector type of inverters with leading global vector control algorithm, the stator current according to the coordinate transform decomposition as the torque current component and the exciting current component, in order to achieve precise torque control. Compared with the V/F control algorithm, it has the advantages of good low frequency torque characteristics, good dynamic response characteristics, high speed control accuracy and so on.

When the inverter has 0.50Hz output that has more than 180% of the high starting torque, to ensure that the suspended starting and low-speed operation of the motor torque, and can be in the speed range of 1:50 (1 ~ 50Hz) to 100% torque continuous operation. Speed deviation is less than 1%. And the use of a high-speed microprocessor and the latest generation of DSP to improve the speed of response, in the lifting equipment to prevent the "slide" is very effective, torque response time of about 0.1 seconds to reach 150% of the torque. Fall, the inverter will be a higher electric potential energy release process, in order to ensure that the frequency converter does not have to be broken down over voltage, the need to add energy consumption braking unit to ensure the normal operation of the inverter. Brake resistance and active power loss in the motor during braking are used to synthesize the braking torque.

1) the traditional control of frequency conversion

1, short wire winding motor rotor winding, the cancellation of the original series resistance speed control scheme; also can design the switch circuit, the original string resistance speed control scheme as a backup plan.

2, the motor brake system of independent power supply, inverter auxiliary control.

3, the original speed control device to transform, so that it can control the speed of the inverter.

4, the inverter fault protection signal string into the safety circuit.

The program transformation of simple equipment investment is small, can be a good use of the original control system, and does not change the operation of the operating habits of workers. It is suitable for hoist system of frequency conversion control system more perfect.

2) complete sets of winch frequency control system

1, using ECF500 vector inverter as the core of the speed control system, using PLC as the core of the control system.

2, according to the configuration can design a variety of different protection. And can be customized according to the needs of the control system.

According to the instructions of the hoist process control and signal system sends out signal, the initiation of the control winding, speed up, slow down, stop process, stable and reliable operation.

(1) the realization of stroke monitoring and position closed-loop hoist control, has improved the depth and speed of display and control functions.

(2) realization of main loop controller for hoist pieces of vacuum and without contacting the attunement of, PLC control, simple hardware configuration, flexible software programming, debugging convenient and small amount of maintenance. At the same time, the closed-loop performance is good.

(3) to improve the hoist operation safety, reliability and the technical level to control, to reduce the failure rate of the equipment, improve production efficiency, reduce the labor intensity of the operation personnel plays a important role.

(4) safety protection and interlock function. Safety locking loop of the winch operating conditions, only when the normal operation of the external equipment, with driving conditions allowed hoist operation, safety locking circuit of the hoist the full weight of the fault, fault in the event of hoist immediately enter the emergency brake, troubleshooting before it can continue to run.

(5) perfect integrated backup protection function.

(6) by means of a photoelectric encoder to achieve digital detection and control of the running speed and position on the winch and improve the system control accuracy and reliability.

(7) double redundancy of safety circuit, at least one way software safety circuit, all the way hardware safety circuit.

(8) PLC itself fault such as "crash", "battery voltage low" "data transmission error" should be able to reliably detect and take appropriate measures to protect.

(9) speed detection and depth detection of the problem and the other way under normal circumstances should be able to use the PLC to speed the speed limit.

(10) automatically send location signals, such as deceleration, stop, fixed point, over the volume signal; important points such as deceleration, over the volume has two or more common role.

(11) the speed and depth are completely separate and compared to each other, the time interval is not greater than 1 second, speed, depth is not the right situation will immediately take the necessary measures to prevent the expansion of the accident.

四、Concluding remarks

Yi chuang fei ECF500 vector frequency converter with its excellent performance, greatly improve the stability and safety of the traditional hoist operation, reduce the equipment maintenance work. Yi Chong Fei electric hoist custom control system set the number of security technology and automatic control functions, winch equipment manufacturers provides full set of electronic control solutions, also can make the old hoist rejuvenated. Since the introduction of the use, access to the user's praise, but also to solve the problem of a large number of mechanical manufacturers of electronic control, and achieved good social and economic benefits.