light industry

Application of ECF300 vector inverter in sand saw

2016-05-13

一、preface

Sand saw in the stone industry is very common. Almost all of the stone processing enterprises, need sand saw, with processing speed, high product quality advantages. There are three major problems in the operation of the sand saw that the user has been working on:

(1) how to improve the slab quality and production efficiency, reduce the loss.

(2) how to save the high cost of electricity.

(3) how to prolong the service life of the sand saw (maintenance period).

Problems existing in the electric control system of the original sand saw:

(1) due to the current equipment is not perfect, the speed of equipment can not be adjusted, can not achieve the best production efficiency.

(2) the sand saw motor adopts the star / delta starting method, the starting current is large, and the impact on the equipment and the power grid is large.

(3) the speed of the equipment can not be adjusted smoothly, and the processing technology can not be adjusted according to the material.

二、Design and working principle of the frequency conversion system of sand saw

Our company uses ECF300 series high performance vector frequency converter to carry on the transformation to the sand saw. By adjusting the running speed of the motor, the sand saw can start at a low speed, and the current impact can not occur. Normal operation at high speed, improve production efficiency. Production is about to end at the end of the low speed operation, reduce the chance of drawing board. Stop or emergency stop using the brake system, shorten the stop time. To achieve the best effect of the sand saw in different working conditions.

三、 Solution and effect of frequency conversion system of sand saw

1, program:

(1) in the control method without changing the original equipment, increase the speed regulation function, start at a time when you can, do not need to start several times.

(2) network security network: surge voltage greatly decreased, significantly reduced the inrush current; power grid network: good end conditions to the greatest extent reduce the network load.

(3) reduce the loss of raw materials, reduce equipment wear and tear.

(4) energy conservation and energy conservation, reduce power consumption.

2, effect:

(1) the original operating system and security protection, the use of variable frequency speed control. To implement processing method according to different materials and different materials cutting process, improve the slab quality and production efficiency. Material cut, the lower speed, zigzag, completely cut into the rock, and accelerate the operation, so it is not easy to appear speed skate. Stone does not appear wavy. When the final cut to ten cm, the lower the speed, is not easy to board. Cut rotten material or the stone cracks, lower speed, while lowering the cutting speed, the slow speed can decrease the impact force, the stone is not easy to be broken is not easy to board and reduce the loss. Can help stone processing enterprises in technology to achieve their own unique processing technology.

(2) through the inverter to digest sawing machine works in the process of transient surge voltage and surge current, and do not install the inverter compared, equipment startup / switching, crankshaft reciprocating internal surge and transient change less and other equipment fibrillation almost no. Directly reduce the network load, the protection of the safe use of electricity.

(3) to improve the technology of variable frequency speed regulation can reduce the loss of raw materials, improve the output rate, reduce the cost and improve the competitiveness. To eliminate the device hard start stop, reduce the transmission, moving parts wear, speed linear adjustment, so that the lubrication system and transmission, moving parts synchronous warm-up input. To extend the service life of the equipment, reduce the number of overhaul, improve the utilization rate of equipment.

(4) reducing power consumption, saving electricity and reducing production costs and improving profitability.

(5) the maintenance is simple, this machine uses the dust and corrosion protection design, does not need to carry on the special maintenance.

四、 Problems to be noticed in frequency conversion speed regulation of sand saw

(1) over current problems: the sand saw has a lot of inertia, so when the current is relatively large, so the choice should be the choice of frequency converter than the motor power level.

(2) over voltage problem: since the device has a motor through a belt to link the flywheel, and then through the crank link saw blade, the flywheel in the work of the regeneration voltage, resulting in frequency converter overvoltage protection phenomenon. Should be appropriately extended plus deceleration time or add the braking unit and braking resistor.

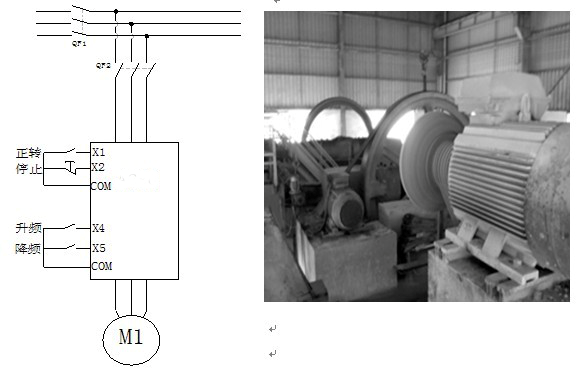

五、Wiring diagram

六、Concluding remarks

To sum up, the frequency converter in the stone industry application to accomplish a great deal, is the future development direction of the technology is not only energy-saving, more is the main regulator of the good performance, to improve the product quality, enhance the competitiveness of enterprises.