light industry

Application of ECF100 inverter in food packaging machine

2016-05-13

一、summary

With the improvement of the degree of automation, the operation, maintenance and daily maintenance of the packaging machine is more convenient and simple, and the professional skills required for the operator is reduced. Product packaging quality is good or bad, is directly related to the temperature system, the precision of the engine speed and the stability of the tracking system.

The pillow type automatic packaging machine with the leading and most mature and reliable technology design and production, brings together the essence of years of experience in the field of packaging machinery, the packing machine to the massive food packaging by various packaging composite membrane, is very suitable for the needs of the broad masses of users in China.

二、working principle

The control core of packaging machine is the tracking system, which uses the positive and reverse direction tracking, which further improves the tracking accuracy. After the operation of the machine, marking film sensor continuously marked on the measurement of the film (color), and the position of the mechanical part of the micro switch is tracing the machinery, the two signal sent to the PLC, after operation procedures, by PLC output Y1 (Chase) and Y2 (trace) tracking control motor tracking of the pros and cons of tracking, error of packaging materials in the production process of discover and can accurately give compensation and correction, to avoid the waste of packaging materials. If the detection is still unable to meet the technical requirements after the predetermined number of times, it can be automatically stopped to check to avoid the production of waste products.

三、The composition of the electric system of the automatic packaging machine

Although the application function of the transmission system of food packaging machine is relatively simple, the dynamic performance of the transmission has higher requirements. Therefore, it is necessary to consider the dynamic technical specifications of the frequency converter, and the high performance frequency converter can be used to meet the requirements of the process.

3.1 the electrical part of the automatic packing machine is generally composed of the following components:

(1) the main control circuit is composed of frequency converter and programmable logic controller (PLC).

(2) the temperature control circuit is composed of an intelligent temperature control meter, a solid state relay and a thermocouple assembly, the temperature control is accurate, the display is intuitive, and the setting is convenient.

(3) by the photoelectric switch, electromagnetic proximity sensors, etc. to achieve multi-point tracking and detection.

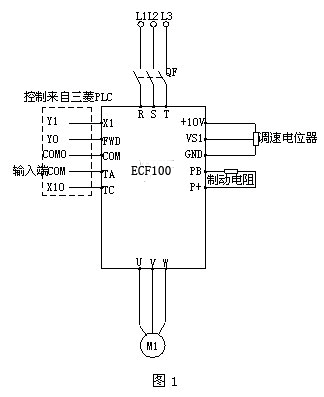

3.2 transducer wiring diagram as shown in figure 1:

四、Yi chuang fei features of fly ECF100 inverter

yichuangfei ECF100 inverter can meet the requirement of packaging machine, because it has the following characteristics:

(1) the automatic compensation control technology of slip frequency is used to automatically modify the frequency in order to achieve the stability of the motor speed when the load changes.

(2) with high stability and fast dynamic response, can meet the requirements of high performance transmission control. Reduces the time and economic losses caused by the failure of the transmission system. Have lower maintenance costs.

(3) with the advantages of rich functions, stable performance, small size, low noise operation, etc..

五、Application of ECF100 frequency control several benefits

(1) simplify the transmission system, greatly reduce the failure rate, reduce the maintenance costs of enterprises.

(2) to increase production and reduce costs. Can improve the production technology, so that the product yield and quality are improved, and can effectively save costs and achieve maximum profit.

(3) to achieve the control of software, improve performance.

(4) through the torque compensation, to prevent the stall and restart and other functions, the realization of non trip operation; so that the production of product quality stability, efficiency and improve the quality of the product.

六、Concluding remarks

Due to the adoption of the variable frequency speed control, significantly reducing the transmission chain, improves the stability and reliability of the operation of the machine, reducing the noise of the machine is running, to ensure that the packaging machine, and low loss, automatic detection, multifunction, full automatic high technology level.