light industry

Application of frequency converter in the energy saving reconstruction scheme of fan

2016-05-13

一、introduction

According to the design rules of thermal power SDJ-79, the air flow margin of the coal-fired boiler is 5% and 5% ~ 10% respectively, and the wind pressure margin is 10% and 10% respectively. Design process is difficult to compute the pipe resistance, and considering the problems occurred in the running for a long period of time, usually the system maximum air volume and pressure margin as the selection basis, but fan model and serial is limited, often choose not to appropriate wind models, is to rely on, by a margin of more than 20 ~ 30% more common. Therefore, the fan operation, only by adjusting the opening degree duct damper or baffle to meet the requirements of the production process of air. Mechanical characteristics of wind machine torque characteristics for the square, the fan is running. By adjusting the throttle or air duct baffle opening to adjust the air volume of the fan, said for the throttle. In the throttling process, fan inherent characteristics of the same, only by small damper or baffle opening, artificially increase the pipeline resistance, thereby increasing the loss of pipeline system, is not conducive to energy saving operation of the fan.

By changing the speed of the fan, the wind speed of the fan can be changed to adapt to the need of the production process, which is called the speed regulation control of the fan. Fan speed control mode to run the most energy saving, the highest overall efficiency. AC motor speed control mode, frequency control of motor speed is, the optimum speed regulation scheme, it can realize the stepless speed regulation of the fan, and can be conveniently to form a closed loop control system, constant pressure or constant flow control.

Power saving principle of fan

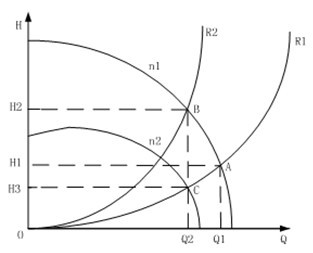

As shown in the figure for the wind pressure Q wind H- curve characteristic diagram:

N1- represents the characteristics of the fan at the rated speed;

N2- represents wind speed characteristics of landing at the speed of N2;

R1- represents the resistance characteristics of the wind turbine pipe resistance;

R2- on behalf of the resistance characteristics of the wind turbine pipeline resistance increased to a certain array.

When the pipeline characteristic curve R1 works, the working condition point is A, the flow pressure is Q1, H1, the power of the wind turbine is directly proportional to the product of H1 and AH1OQ1, which is proportional to the area of Q1. Because the process is required to reduce the air flow to Q2, in fact, through increased network pipe resistance, the fan operating point moves to the R2 B, pressure increases to H2. When the wind machine power is proportional to the H2Q2 area, namely proportional to BH2OQ2 area. Obviously, the power of the wind turbine is increased. This adjustment is simple, but the power consumption is not conducive to energy saving, is a high cost of operation in exchange for a simple control.

If you use the frequency conversion speed regulation, fan speed by N1 decreased to N2, then working point by point a shift to point C, flow is Q2, pressure by the H1 to H3, when variable speed fan required power is proportional to product of the H3 and Q2, which is proportional to CH3OQ2 area, by the map shows that power reduction is less obvious.

二、Transformation scheme of frequency conversion

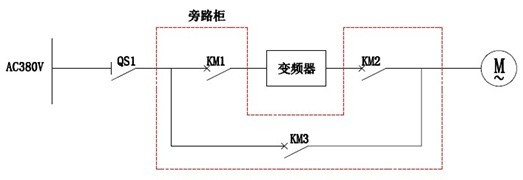

According to fan configuration feature as follows frequency conversion scheme:

(1) the fan is equipped with frequency conversion system (chart);

2) to retain the original power frequency system and its linkage mode, and the frequency converter system for standby.

三、Characteristic of frequency conversion and energy saving system

1) by Yi Chuang Fei ECF500 inverter, wide speed range, variable speed range to meet the requirements of various speed regulation equipment, frequency range 0.00-400.00Hz adjustable;

2) control precision is high, the frequency converter digital setting resolution is 0.01Hz, the simulation setting resolution is 0.2Hz;

3) control function is strong, can meet all kinds of different control system, through the terminal can be connected with all kinds of frequency setting signal, such as: 0~10V, 4~20mA. Can be controlled by terminal inversion and other operations;

4) converter ECF500 can and host computer or programmable controller (PLC) communication, remote set or modify the parameters of the frequency converter, frequency converter monitoring the running status information to industrial Ethernet, to achieve centralized control;

5) protection function is complete, to the overvoltage, under voltage, over current, overload, overheat and so on to give protection.

四、Summary

In the field of fans, pumps, compressors and other applications, the introduction of variable frequency speed regulation control technology, to achieve a good energy saving effect, at the same time, it reduces the motor starting on the grid impact, to improve the power factor of the equipment, prolongs the service life of the mechanical system, enhance the reliability of the system. In addition, because of the strong protective function of inverter, the devices to a good protective effect, effectively reducing maintenance cost of the equipment. In recent years, with the continuous popularization and application of frequency control technology, from the perspective of practice, a good economic effect and social effect, and also be widely recognized by users.