light industry

Application of inverter in mining sand on the reformation

2016-05-13

Sand is one of the most basic materials in the construction industry. How to get a large amount of sand, meet the needs of modern architecture, in numerous sand equipment, suction sand is one of the most widely used equipment. Suction sand mostly for use of mobile operations, inland river dredging ship, dozens of tons of sand mining capacity, to thousands of tonnes. Large river mining mechanization large junk and a high degree of automation, a ceiling sand can become a production unit can implementation of sand and gravel mining separate selection process.

一、Operation status and analysis of equipment before reconstruction

Introduction of equipment operation:

Sand with water absorption, thrust high-pressure water jet out of the water column of sand, sand, etc. under the action of the water pump is composed of a sand suction pipe conveying to the ship, then after the water washing. The sediment were separated, then use the bucket wheel sand from the cleaning tank is transported to the sediment storage bucket, finally through a belt output will be sent to the sand barge on sand transport, to complete the process of sand mining.

Problems in equipment operation:

Pumping sand process, the wheel and bucket and conveyor belt while the self coupling voltage starting, the starting current is quite large. Therefore, on cable and the generator capacity are were selected according to the maximum current value, increase the cost of electrical equipment. Secondly, in the sand mining work, when the amount of sand pumping is insufficient, the wheel bucket and the conveying belt will be started as usual, resulting in a large amount of waste of electric energy. Third, when the amount of sand pumping is insufficient, in order not to cause the waste of electric energy, the bucket and the conveyor belt are bound to be shut down, the frequent start of the impact of the equipment is larger, and the maintenance of the equipment is not benefit. And because of the conditions necessary, dumpers and transport belt output need speed. The original speed control using the gearbox, the use of the gearbox has a lot of defects, such as can not be used for linear speed, change the belt pulley is too cumbersome, labor intensity, mechanical wear, and a waste of energy, etc..

二、Advantages of using frequency conversion

According to the above, we on the sand suction bucket wheel and frequency conversion technique is adopted to transform the conveyer belt original speed way exists many problems.

1, the use of frequency converter soft start function, reduce the impact of bucket wheel and belt, and reduce the motor is started, the generator current impact; soft start current only self coupling voltage starting current of 0.5 times, not only to enhance the capacity of the generator and reduce the lines of the damage, and can reduce the motor start hull vibration.

2, the use of frequency converter can realize stepless speed, when the pumping less sediment, reduce the output frequency of the inverter, for devices operating at low speed, in such a way as to achieve energy saving, and the cleaning sand pumping from the wash basin.

三、Transformation scheme and requirements

1, the Yi chuangfei ECF100 series general inverter

2, inverter installed in the lower part of the hull, and the hull at the top of the control room is farther, the inverter panel led to the control room, to facilitate the control and view the status of equipment.

3, inverter using remote control, all control lines are shielded wire.

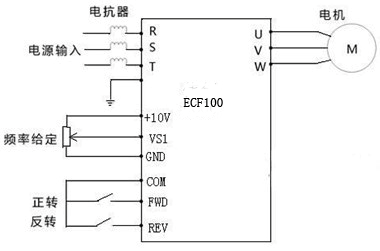

四、Inverter wiring diagram

五、Parameter table

|

Serial number |

Set value |

Parameter significance |

|

E-01 |

1 |

Terminal control |

|

E-02 |

2 |

Frequency channel |

|

E-13 |

10 |

Acceleration time |

|

E-14 |

10 |

Deceleration time |

|

E-18 |

0.5 |

Torque boost |

|

E-34 |

1 |

Free parking |

六、summary

By using Yi Chong Fei converter of sand on the bucket wheel and a conveying belt used in reconstruction of the and reduce the starting motor when the instantaneous impact current, to solve the traditional sand mining can not linear speed, complex operation, labor intensity is large, sand mining after transformation, simple operation, high efficiency, lower energy consumption, running more stable and reliable.

Note: because the load is heavy, it is recommended to use the inverter to enlarge the two gear; because the hull line is too long, it is easy to cause interference!