light industry

The application of ECF500 in rubber machine

2016-05-13

一、Open rubber mixing machine

Open rubber mixing machine or machine or mixing machine, also called double roller kneading machine. It through two level placement and to different line speed of relative rotation of the roller, rubber raw material shear, extrusion the plasticizing, mixing, made in line with the requirements of production and processing of blank. Open rubber mixing mill for rubber plastication, mixing, thermal mixing and tabletting and so on, is mainly composed of a roller, a frame, a bearing, adjustable pitch device, heating and cooling system, accident parking device, lubricating system and electrical control system components.

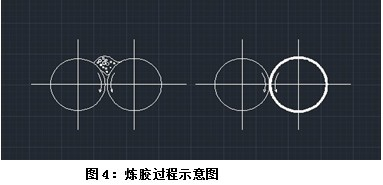

Its working principle: two roller mill with different speed relative rotation, when the glue applied to the roller, roller extrusion at the same time, due to the role of adhesion force and friction is drawn into the two roller gap, the glue in the gap by strong extrusion so as to achieve the sizing material processing. After discharged from the roll gap in the material, due to differences in the two roller surface temperature and velocity and coated on a roller, return to between two rollers, so repeatedly, complete mixing.

Two, mixing machine frequency conversion control system

The control system through in between the mixing machine motor and power supply installation of Yi Chong Fei converter ECF500. At the same time in the inverter control panel on the part of control circuit connection, realize the mixing machine frequency conversion stepless speed regulation, to achieve a smooth start and speed of the motor of the mixing machine is adjustable. The reverse function terminal can be realized conveniently in the roller plug when the motor reversal back glue, easy to operate. In addition to do a power frequency switch standby circuit to prevent the failure of the inverter in case of failure to affect the production of the factory.

三、Yi chuangfei inverter in the application effect in Jiangsu in a rubber factory renovation rubber machine

1, through the inverter DC bus support capacitor can play the role of reactive power exchange, greatly improve the input power factor of the device, and do not have to buy power factor compensation device.

2 and frequency converter to realize the soft start of the motor, eliminating the frequency start impact on power grid equipment and, to avoid tripping fault of other electrical equipment may be caused by, and prolongs the service life of the shaft, gear, reducer, lubricating system, cooling parts and mechanical parts, to achieve a better safety in operation.

3, inverter stepless speed regulation can be according to the actual production needs convenient setting roller reversing, speed and size and acceleration and deceleration time make operation more simple and convenient. Yi Chong Fei converter with industry leading automatic torque to enhance performance of motor control, to maximize the equipment working efficiency, reducing the waste of electric energy.

4, ECF500 inverter with under voltage, over voltage, input phase, over current detection, overload detection and other detection protection function, so as to ensure long-term stable operation of equipment.

5, about the energy saving effect of the installation of the inverter to the mixer after

1. Power factor compensation energy-saving: reactive power not only increases the heat loss and equipment, more important is power factor leads to a reduction in power grid decreased, lots of reactive power consumption in the middle of the line and equipment use efficiency is low, serious waste, rubber mixing machine motor power factor general at about 0.7, after the use of variable frequency speed regulating device, due to the role of filter capacitance inside the converter, cos phi is generally greater than 0.9, improve power factor, transducer actual input current is reduced, thereby reducing the loss between the grid and the inverter and power supply transformer copper loss, and reduce the reactive current on the grid.

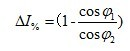

After the power factor is improved, the current drop rate of the power distribution system after the compensation of a single motor is:

The type cos, with 1 for the operation of power factor compensation before motor;

Cos 2 to run the motor power factor compensation.

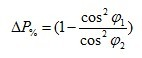

The drop rate of the power distribution system to the single motor after compensation is decreased:

②In operation process, the inverter ECF500 use energy-saving operation function can according to the load conditions automatically calculates the optimum output voltage when the load is light can reduce the output voltage) is supplied to the load to achieve energy-saving effect.

(by monitoring the actual, at present the mixing machine customer on-site mixing machine running current generally only 50% to 60% of rated current, load rate is low, the use of energy-saving operation function can achieve a certain energy-saving)

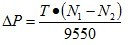

That is, the input power of the motor is proportional to the speed of the rotating speed, and the power is saved when the variable frequency speed regulation is adopted:

Therefore, the power and speed of the system before and after the speed difference is proportional to the speed difference is greater, the more significant energy saving.

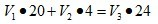

In the mixing machine at customer site, we found that mixing machine and material mainly rely on workers to artificial fillers, in the middle there is a mixing machine material idle time and in rubber mixing machine for 20 seconds, then idling 40 seconds, for example (at this time mixing machine motor has been 50Hz operation): We can through reduced motor speed to achieve in the whole 24 seconds of time mixing machine uniform finished equal amounts of plastic material and not to machine idle time, i.e.

The V1 to the linear speed of the roller motor 50Hz run the corresponding, V2 due to the absence of processing compound, so zero. This time period is 24 seconds, the speed after the V3 roller linear velocity of motor running 41.7Hz corresponding, that we through the inverter will motor speed is set to 41.7Hz can complete the same amount of production.

According to the theoretical calculation, regardless of other factors, a single motor through the speed of energy saving rate of 16% or more. Actually, using inverter power saving rate need to consider including power factor improvement of energy-saving, through the realization of automatic power saving function of speed and frequency converter internal energy, inverter itself is only a small part of the components work loss, actual power saving rate needs to be to the actual measurement.

The rubber plant a total of more than 70 55KW~185KW open smelting machine, dense mill equipment, accordingly we according to the experience can be a rough estimate, all rubber mixing machine equipped with Yi Chong Fei ECF500 series inverter for technological transformation and energy-saving, power-saving rate is about 8% ~ 20% or so. According to the previous device power consumption of 20 million per year, after the transformation, the annual electricity savings in 150<