light industry

Application of ECF300 in the process of seamless steel tube

2016-05-13

一、preface

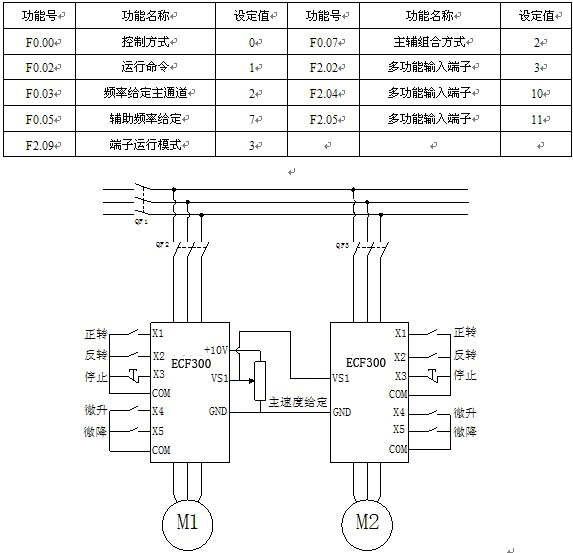

The process of seamless steel tube is processed by pre - stage extrusion, high temperature seamless welding, post - extrusion molding and cutting. Motor with large torque output, at the same time, in the process, to speed stabilization accuracy requirement is relatively high. Otherwise, extrusion molding steel tube structure is not uniform, unstable thickness affect the quality of product. In the process of start control. Before forming and molding, is by ECF300 inverter (4kw) with no PG vector control drive and their frequency are given by the VS1, auxiliary frequency given by the UP/DW, with main and auxiliary superposition of the frequency of a given form of frequency setting. Positive inversion of starting and stopping and motor using terminal control.

二、Advantages of ECF300 in the application of seamless steel tube processing

1, David chuangfei ECF300 PG inverter on 0.1Hz, can be rated torque output 200%.

2, high speed precision, error control in + 0.2%, and dynamic response fast.

3, inverter power supply board, control board using special insulation treatment, strong corrosion resistance.

4, the radiator with a unique duct design, can be stable at a higher ambient temperature.

三、Parameter setting and wiring diagram

Parameter setting:

四、Concluding remarks

After a period of practical application show that the Yi a fly ECF300 vector of the inverter is running well, the control effect is good, the failure rate is low and moderate investment, favored by the vast number of manufacturers.