light industry

ECF300 in sugar crushing machine on the application

2016-05-13

一、summary

With the inverter in the application scope expanding, using frequency converter to save energy and improve production technology and improve the level of production automation, has been widely used in all walks of life, and achieved remarkable economic and social effects.

At present our country sugar in sugar production has been widely used in the inverter to achieve energy saving. In addition to in fan and water pump widely used in order to achieve the purpose of saving energy and reducing consumption, the frequency converter has been the core equipment in the sugar producing press on and successfully replaced the old traditional control method. Through improving the production technology of the press, the extraction rate of the press is improved, and the purpose of saving energy and reducing consumption is achieved.

I company for sugar press machine to the production process, in particular the use of ECF300 series high performance vector inverter of the sugar press frequency transformation, and achieved remarkable economic benefits. Only one crop basically recover the entire renovation investment, praised by users.

二、Feasibility analysis of reconstruction scheme

The extraction rate of the press is influenced by many factors:

1, the influence of mechanical characteristics. Sucrose rich fibers in the press, the juice will for high-voltage separated from the fiber, but at the exit for pressure disappeared, fiber with its expansion at the exit will absorption have been squeezed out from the part of sugar cane juice. Furthermore squeezed principle. The press is not possible from the fiber out of all of the sugar cane juice, so mechanical characteristics itself will caused part of cane juice loss.

2, the impact of production technology. The efficiency of cane morphology and fragmentation directly determines the first out of the press. Cane fragmentation to sugarcane juice press, exudation. Shredder is conveyed out uniformity cane layer thickness, will directly affect the extraction rate of sugarcane juice. If cane layer too thick, the pressing is completely, the cane juice extraction rate lower; if the cane layer is too thin, pressed sugar cane layer, bagasse moisture content is too high, the cane juice extraction rate decreased. To ensure that the water content of bagasse can reduce high extraction rate.

3, the influence of mechanical properties. Machinery will because of wear caused by the decline in the performance, especially pressing roller due to wear and deformation, and the gap between the larger, crushing efficiency is reduced, to the cane juice extraction rate decreased.

Through the above analysis, we know the factors that affect the extraction rate of the press. Because of the original control system throughout the speed is not adjustable, so in the production process and mechanical deviation cannot to speed made timely adjustment, resulting in for machinery technology and change the press sugar cane juice extraction rate decreased.

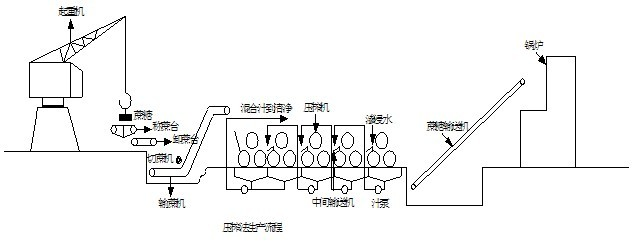

三、Converter reconstruction scheme

From the sugarcane shredder conveying out of about 8% ~ 15% of the thickness of the time will not up to the requirements. Because of the original control system of all the speed is adjustable, so that the average cane juice extraction rate of less than 96% to 94%. Take the lower the rate of sugarcane juice and the greater the loss, the lower the yield. Through the use of variable frequency speed, cane layer thickness in, press speed increased the cane layer rapidly press; in the cane layer thickness thinning, the press speed decreased, the cane layer thickness automatic rose to normal thickness after pressing, improve the press extraction rate of 0.15% ~ 0.3%, at the same time, because the motor speed is reduced, energy consumption is reduced, so as to achieve the purpose of energy saving 5% ~ 10%.