light industry

Application scheme of ECF300 vector transducer instead of torque motor

2016-05-13

一、preface

Torque motor is a kind of special motor with soft mechanical properties and wide speed regulation range. The shaft of the motor is not a constant power output power but a constant torque output power. Torque motor include: DC torque motor, AC torque motor, and brushless DC torque motor.

The construction principle of torque motor: when the load is increased, the speed of the motor can be reduced, and the output torque is increased, and the balance between the load and the load is maintained. Torque motor blocking torque is high, blocking the current is small, can withstand a certain period of time to stop running. Because the rotor electric Yin high, loss, the heat generated, especially in low speed and stall more serious. Therefore, the motor on the back end cover with separate axial or centrifugal fan (small output torque 100 frame size and all the following except), for forced air cooling, torque motor with controllable silicon control device, voltage and speed regulation, speed range of up to 1:4, the speed change rate is less than or equal to 10%. The motor torque characteristics make it suitable for winding and unwinding, plugging rotor and speed occasions and other uses, is widely used in textile, wire and cable, metal processing, paper making, rubber, plastic, printing machinery and other industrial fields.

二、yichuangfei ECF300 vector inverter alternative application scheme of torque motor

Yi Chuang Fei ECF300 vector type of converter by replacing the application scheme of torque motor is used ECF300 vector inverter, with with ordinary three-phase asynchronous motor, torque motor and torque motor controller substituted. The scheme has the advantages of simple implementation, low cost, no need of maintenance work, and the reliability and the control precision are greatly improved compared with the original scheme.

Yi Chuang Fei ECF300 vector type of inverters with leading global vector control algorithm, the stator current according to the coordinate transform decomposition as the torque current component and the exciting current component, in order to achieve precise torque control. Compared with the V/F control algorithm, it has the advantages of good low frequency torque characteristics, good dynamic response characteristics, high speed control accuracy and so on.

Yi Chuang Fei ECF300 vector inverter standard torque control function, through accurate vector decoupling operation, independent of the current loop torque control is implemented. In the control of torque and speed, the torque control accuracy is 5%, and the torque response speed is less than 20ms. The torque is given in a given way with a given number of given and analog quantities.

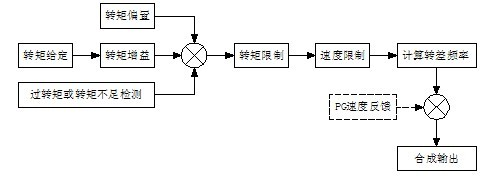

The torque control chart is as follows:

In order to ensure the effect of the replacement torque motor is good, please pay attention to:

1, to know the power level of the original torque motor, motor polarity, system transmission ratio, in the replacement process to ensure that the selected system drive ratio unchanged under the premise of the selection of motor power levels and the number of poles.

2, conditions allow the premise, the best is the inverter motor (low speed operation will be better).

3, in the debugging, self tuning rotation must be disengaged on motor load.

4, in some applications may need to cooperate with the encoder, such as the following occasions need to consider:

(1) when the transmission is relatively large, generally greater than 4, we should pay special attention to;

(2) the material tensile, such as thin film or thin paper;

(3) the frequency converter operating frequency is low, such as the following 5.00Hz;

(4) the torque is less than 5%.

三、Concluding remarks

Yi chuang fei ECF300 vector frequency converter with its excellent performance, greatly improve the stability and the safety of the operation of the torque motor and its control system, reduce the equipment maintenance work. In the rolling equipment, multi-point transmission equipment, rolling mill, printing and packaging and other industries have been widely used by users.