light industry

Application of ECF100 in mold electromagnetic stirring in continuous casting machine

2016-05-13

一、Theory of continuous casting and electromagnetic stirring

With the increasing requirement of the steel quality, the quality of the slab is becoming the most important problem in the process of continuous casting. The inner quality of the cast slab depends to a large extent on the solidification microstructure of the cast slab, which is uniform and compact. But in the actual solidification process of continuous casting billet, due to the fast cooling rate of the molten steel, resulting in cast solidification on the development of columnar crystal, often resulting in the phenomenon of bypass, shrinkage hole segregation, porosity, inclusions aggregation defect.

Due to the effect of electromagnetic field has the characteristics of non-contact, especially suitable for in molten steel of the occasion, continuous casting machine of the electromagnetic stirring (electromagnetic stirring:EMS) technology is a emerged, it can significantly improve the quality of casting billet, so at home and abroad by highly attention and got rapid development and extensive application. At present, the electromagnetic stirring device of the steel plant has become an indispensable equipment for smelting high performance variety of molten steel.

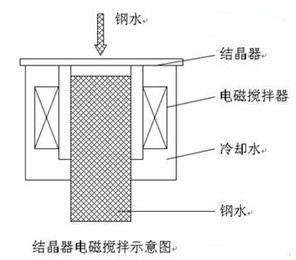

The working principle of electromagnetic stirring is based on the law of electromagnetic induction, and the current carrying conductor in a magnetic field will be subject to the action of electromagnetic force. In this regard, the working principle of electromagnetic stirring and induction motor is the same, the mixer is equivalent to the stator of the motor, the molten steel is equivalent to the motor rotor. The rotating magnetic field is generated by the coil winding of the electromagnetic stirring, and the induction current is generated in the conductive molten steel, and the electromagnetic force is generated by the induction current and the magnetic field. The essence of electromagnetic stirring in continuous casting is to strengthen the movement of molten steel by the electromagnetic force of the electromagnetic force in the liquid phase of the slab. Structure of mould with electromagnetic stirrer is shown.

二、Special requirements of electromagnetic stirring for power supply

Electromagnetic stirring system consists of two parts: electromagnetic mixer and frequency conversion power supply. Molten steel is the reason to be stirred, is due to the stirrer coil excitation of alternating magnetic field penetration into the molten steel billet in, in which produce induced current, induced current and the magnetic field produced by the interaction of electromagnetic force, electromagnetic force in molten steel volume element, so as to promote movement of molten steel. The induced electromagnetic force is proportional to the square of the current intensity. The greater the current, the higher the center magnetic induction intensity. In general, the magnetic induction intensity of the magnetic induction intensity in the crystal area is larger than that of the 500Gs. In order to ensure the requirement of the magnetic induction intensity, there must be a large enough current. This requires frequency conversion power supply must be able to provide a long time a large current, usually in the reach of 400A.

The electromagnetic force and the speed of the stirring of the molten steel in the molten steel are not only related to the current intensity, but also greatly influenced by the frequency of the power supply. Frequency selection mainly and crystalline copper tube permeability, thickness, section and other factors are closely related, which not only affect the amount of the maximum electromagnetic force value, choice is improper, it will weaken the stirring power. In general, in order to ensure the penetration effect of the magnetic field, the best mixing frequency is between 1 and 8Hz. Generally cast slab section, the power supply frequency of the copper tube thick is low; the section is small, the power frequency of the copper tube is thinner.

Due to the thermal effect of high current and molten steel, stirrer coil temperature is higher, in order to heat, immersion blender in cooling water, which requires stirrer coil insulation must be very high, and cause stirrer coil is not cheap. As far as possible in order to extend the service life of the mixer, variable frequency power supply to the principles for the design of low voltage and high current, and to smooth the output waveform to prevent high-pressure peak output voltage of coil insulation damage.

In summary, the frequency conversion power supply of electromagnetic stirring must be able to work in a low voltage, low frequency, high current situation for a long time, to provide the necessary protection of electromagnetic mixer. Addition, usually cases, continuous casting machine enabled electromagnetic stirring, there will be multiple high-power variable-frequency power supply work at the same time, it is necessary to consider to avoid harm to the power grid, the impact of other electrical equipment in normal operation.

三、ECF300 converter is suitable for the characteristics of electromagnetic stirring

Electromagnetic stirring power supply can be divided into two categories: one is the use of discrete components, with the PLC or SCM, industrial control, consisting of frequency conversion power supply; two is the use of modified general-purpose inverter method. Many power companies through research, developed using discrete components of variable frequency power supply, but because of domestic electric power electronic technology and the product process is relatively backward, using only universal control chip and electronic technology, making it more difficult to produce high performance of AC-DC-AC mode of special power supply; and because of the number of components, and production does not have the scale, the manufacturing plant, lack of strict quality control measures, the reliability of the power supply than the mass production of the general inverter to low, high fault rate and when there is a problem is not easy to find the accurate fault. Compared with the assembly of discrete components, the reliability of the power supply is much higher, but not every kind of inverter is suitable for modification. This is mainly because the general type inverter is designed for the control of AC motors, and is not suitable for use as an electromagnetic stirring power supply.

ECF300 frequency converter, compared with the same kind of frequency converter, more suitable for the conversion into electromagnetic stirring with the frequency conversion power supply. ECF300 inverter are arranged inside the DC reactor, can in the electric network voltage instantaneous fluctuation, the rectification part of the protection of the inverter also suppressed the due to the impact generated by the rectifier part of harmonic current of power grid and improve the current waveform of the input to the inverter, enhance the inverter resistance ability of grid voltage surge, also AC reactor also reduces the due to the harmonic current generated by the harmonic voltage and reduce the influence on other systems with a power supply system. Inverter output current waveform is sine wave, waveform distortion rate is small, which is very important for the protection of the mixer coil. In the discrete components of the power supply system is indispensable to the isolation transformer, in the use of ECF300 converter is no longer required.

ECF300 inverter to take a complete protection function, which is to adapt to the harsh environment of metallurgical system, to achieve high performance requirements to provide a guarantee. For example: inverter ECF300 using the three-phase output current detection, and not the conventional two-phase output current signal detection. Therefore, the inverter can according to the detection of three-phase output current value calculated three-phase output current and fast judge the inverter is grounded, reach the earthed protection function, thus making similar transducer creates a low frequency power supply can not achieve the output protection function in the ECF300 converter manufacturing into low frequency power supply can be fully realized. In addition, such as over current protection, ground protection, under voltage protection, over-voltage protection, under load protection, inverter low temperature / thermal protection, overheating protection, input / output phase protection and other protection functions are also available.

四、Specific implementation plan and application effect

No.4 Slab Caster in a steel mill in the design and installation of electromagnetic stirring system of power supply, control system, after full investigation, demonstration, this electromagnetic stirring system in No. 4 continuous casting machine for a long time is demonstrated using electromagnetic stirring in the improvement of continuous casting billet columnar crystal, bypass, pinhole, and equiaxed zone and reduce segregation, reduce or eliminate the center porosity and shrinkage hole effect is very obvious, to improve the quality of continuous casting billet has obvious effect. The ECF300 converter is stable and reliable operation, which provides a basic guarantee for the full play of the electromagnetic stirring system.