light industry

Application of ECF100 inverter in synchronous transmission control system of paper machine

2016-05-13

At present, there are many paper mills in our country, but there are many problems, such as low level of automation control, high energy consumption, quality and yield of paper products in a certain extent. And with the rapid development of social economy, people on paper consumption quantity and paper quality requirements are increasingly high, which requires paper-making enterprises continuously improve the production technology and automation level of production, the paper products to meet the growing needs of the economy.

Two, paper machine production line synchronization control has the following 4 ways

1, the ratio of speed box + sliding speed motor

This method is widely used in the early paper machine production line. Due to the use of electromagnetic slip speed motor waste electrical energy, has been gradually eliminated.

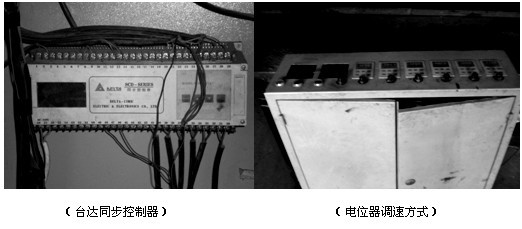

2, synchronous controller +ECF100 inverter + squirrel cage type Y series induction motor

Have multiple input / output. A multi loop high precision potentiometer (2.2K) is used to adjust the synchronization controller, the speed chain mode is set up in the synchronization controller, and then the ~ 20mA/0 analog signal control system is controlled by the 4 ~ 10V analog signal. Advantages: the transformation of simple cost low. Disadvantages: analog signal is vulnerable to interference, accuracy is not high, easy to break the paper, the service life of about a year and a half. (see figure below)

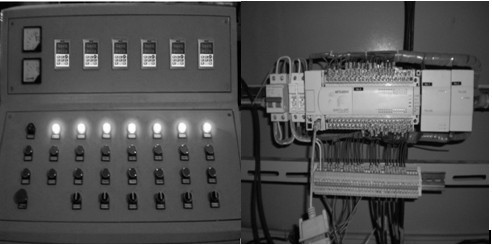

3, PLC host +D/A module +ECF100 inverter + squirrel cage induction motor (Y series /4)

The switch amount (such as button) signal to the PLC, BIN integer / floating-point binary arithmetic, and then the 0-4000 digital value through the D/A module is converted to 4 ~ 20mA or 0 ~ 10V analog signal output to the inverter. Advantages: the linear speed accuracy is higher than the synchronous controller. Blackout can keep memory. Use button instead of potentiometer. Guaranteed accuracy. Disadvantages: high cost of renovation project. The problem of low accuracy is still existed. (the following figure is 6 point synchronous analog output control system using 2 D/A modules)

4, PLC and ECF100 converter for master and slave communication mode

ECF100 frequency converter Modbus communication mode using the master-slave mode of inquiry - the corresponding mechanism, only the main station issued a query, from the station to give the response, the station can not take the initiative to send data. PLC as the main station, to receive external signals (such as buttons), through the 485 communication ports, and as the frequency converter from the station to communicate, send commands and receive data. And can be real-time monitoring by touch screen.

Due to the adoption of the master-slave communication mode, high synchronization accuracy, almost no interference. And eliminating the paper machine industry, the traditional control method used in the D/A module.