light industry

Application of ECF100 inverter in high speed rotary cutting machine

2016-05-13

The traditional large wood peeling machine control system adopts EUROTHERM DC controller system composed of +PLC + 590. A wide range of applications in the wood processing industry, its complete process is as follows: on the wood machine - rotary cutting machine - winding, shear - stacking. Is to cut the wood into pieces of wood, used in the manufacture of plywood and so on. The following is only a part of the transformation of the rotary cutting as an example.

When using ECF100 instead of 590 series controller must meet the following requirements.

1, to ensure the speed of the original wire (50 - 100M) and cutting accuracy.

2, the start-up process is rapid, cutting strength is strong, uniform.

3, according to the actual diameter of the log, the feed speed of rotary cutting machine automatic adjustment, ensure the constant thickness of wooden tablets.

Function and characteristics of ECF100 converter after transformation:

Diameter of the log 1, the grating ruler or displacement sensor automatic monitoring, real-time computing tool feed rate, cutting veneer thickness uniformity, high precision, smooth surface.

2, the rotary cutting machine parameters can be set online, cutting thickness can be adjusted continuously.

3, speed range 0~400.00Hz fully meet the requirements of the high frequency output of rotary cutting machine in the late stage.

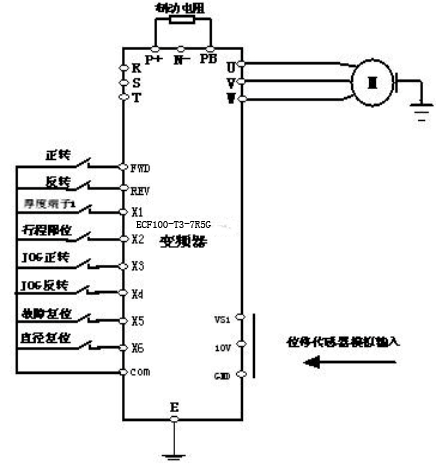

4, 0.5Hz start torque can reach 150% of the rated output, to ensure that the motor has a strong cutting force in the low speed heavy cutting. Application wiring diagram:

Connection description:

1, a braking resistor is adapted according to the actual models. (some models do not need to configure) details see Yi Chuang Fei ECF100 inverter manual;

2, the source tree diameter by displacement sensor feedback calculated. Displacement sensor analog input VS/VF corresponding the maximum diameter of the log is 10V (IS/IF is 20mA).