light industry

Application of ECF100 series inverter in industrial washing machine

2016-05-12

First, an overview

In recent years, industrial washing equipment especially to washing equipment based, application of the frequency converter is becoming more and more popular, inverter for the industrial washing equipment has brought the new technological revolution, from the earliest of the speed of semi automatic washing machine to two double speed motor to achieve the four speed automatic washing machine, finally, the development of only a motor can realize multi rate of modern washing machines.

Two, industrial washing machine working process

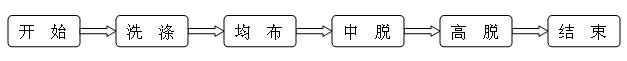

First with water, positive and reverse rotating washing 25 minutes, after washing drainage, entered the stage of dehydration, dehydration stage included three processes of uniform, removal and high degree of cloth is under water and anhydrous, to higher than the washing process speed forward rotation 1.5 minutes, clothing and uniformly attached on the washing machine at the inner side of the roller, to make subsequent dewatering process smoothly; drainage and raise the speed to a moderate dehydration process (2 minutes), and then re entering high speed dewatering process (5 minutes), the clothes wet rate fell to the required level. Its work flow chart as shown below:

Three, industrial washing machine requirements

Industrial washing machine requirements inverter can provide high torque, multi segment speed, wide voltage range, automatic compensation and convenient means of communication; performance is stable, can adapt to various hotels, hotel laundry of high temperature and high humidity environment; requirements inverter can meet the requirements of industrial washing machine specific washing process requirements and specific groups of customers service.

There are two ways to set the speed:

(1) the operation speed of each phase is set directly on the frequency converter in a multi speed mode.

(2) through the washing machine special control PC computer board, in order to set the speed of the various stages of communication.

The running speed of each phase is:

Washing: 30rpm, uniform: about 60rpm, and about 400rpm, high: 700 ~ 800rpm.

Four, Yi chuangfei application of ECF100 converter on characteristics of industrial washing machine

A fly ECF100 type inverter performance is excellent, reliable quality, high ratio of performance to price Yi, simple adjustment, convenient operation, especially for industrial washing machine technology requirements, the V / F curve self regulating technology, according to the status of washing and automatic diagnosis of V / F curve adjustment, the washing machine start steady, the current is reduced and the customer using the stable operation in the process, by the users.

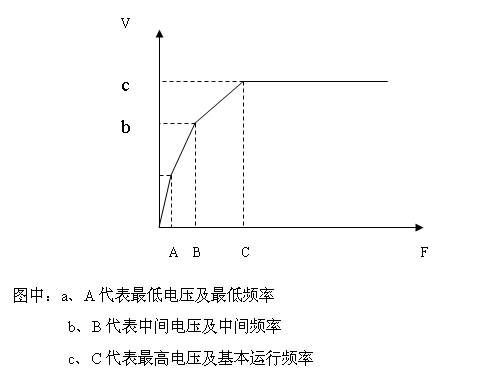

The ECF100 type frequency converter not only has the special V/F curve automatic lifting function, but also can optimize the V/F curve according to the actual need in each link, and also has the powerful multi segment speed function (15 segment speed). In industrial washing machines, the general requirements of the V/F curve are as follows:

(A, a) point can be at the origin, the range of A is roughly between 0 to 4.00Hz, the range of a is roughly between 0 to 25V, and the adjustment (A, a) point can affect the starting torque of equipment, thus affecting the washing speed of equipment. If (A, a) point down, then the device's start-up frequency is low, the washing machine start slow and steady, the low frequency of the transducer requires a large torque.

(B, b) the adjustment of the point is directly affect the running current of the device when washing, which is very important point. If (A, a) and (B, b) between the slope of the large, that is, the V/F curve is steep, the running current will be great, but the slope is too slow, it needs to be adjusted according to experience.

Below with 100kg type washing machine as an example:

(A, a) points: 2.00Hz, 24V, (B, b) point: 25.00Hz, 112V, (C, c) point: 50.00Hz, 380V

After testing on the 100kg type washing machine (transducer for ECF100-T3-011G, 11kW), the data are as follows:

|

|

Starting current(A) |

Operating current(A) |

speed(rpm) |

frequency(Hz) |

|

wash |

11.8 |

11.3 |

32 |

7.06 |

|

Uniform |

13.1 |

7.6 |

60 |

11.66 |

|

be hit by take off |

7.2 |

1.9 |

350 |

65.36 |

|

Gao Tuo |

6.7 |

2.8 |

653 |

123.6 |

The data is repeated two days of repeated trials, during which there have been four hours of continuous operation, no accident, the frequency converter temperature rise is very small. In addition, in the 30kg, 50kg, 70kg models have reached a similar conclusion. 100kg type full automatic washing machine when the running current is about 30A, must use the 15kW inverter. It can be seen that the Yi chuangfei inverter in washing equipment cost reduction plays an important role. AC60 type inverter is indeed a suitable for washing equipment, the use of high-quality inverter.

Five, parameter setting

|

Function Num |

feature name |

Set value |

Function Num |

feature name |

Set value |

|

E-01 |

Run command given channel |

1 |

F-01 |

Multi speed 1 |

5 |

|

E-02 |

Frequency given main channel |

0 |

F-02 |

Multi speed 2 |

6 |

|

E-13 |

Acceleration time |

15 |

F-30 |

Fault alarm |

1 |

|

E-14 |

Deceleration time |

45 |

H-01 |

Self setting voltage V1 |

15 |

|

E-09 |

Maximum frequency |

130 |

H-02 |

Self setting frequency F1 |

4 |

|

E-10 |

Upper frequency |

130 |

H-03 |

Self setting voltage V2 |

30 |

|

E-17 |

Custom curve |

4 |

H-04 |

Self setting frequency F2 |

25 |

|

E-16 |

Digital given frequency |

8 |

H-05 |

Self setting voltage V3 |

100 |

|

H-70 |

Communication setting ratio |

1 |

H-06 |

Self setting frequency F3 |

50 |

|

F-09 |

1 speed setting |

11.66Hz |

F-10 |

2 speed setting |

65.36Hz |

|

F-11 |

3 speed setting |

123.6Hz |

F-03 |

Multi speed 3 |

7 |