light industry

The application of ECF300 inverter in the rotary cutting machine

2016-05-12

First, an overview

Forest resource is scarcity, the timber resources integrated and efficient use of the in front of the pendulum in the woodworking equipment manufacturing industry and wood processing industry has become an important topic. The multilayer board manufacturers in the production process of the single plate, using the traditional have card centering log rotary cutting machine for processing. This processing method has high precision and good quality. However, due to the heart card, the rotary cutting diameter logs in a 200 mm, will not be able to card peeling machine; and log with small diameter log reduction in stiffness, rotary cut veneer quality is poor, then if the remaining wood core abandoned or processed into wood core plate will lead to great waste of raw materials, thereby increasing the production cost of the single board. So manufacturers generally use non card log rotary cutting machine for the remaining wood core again rotary cutting, make the full use of raw materials.

二、The working principle of round cutting machine

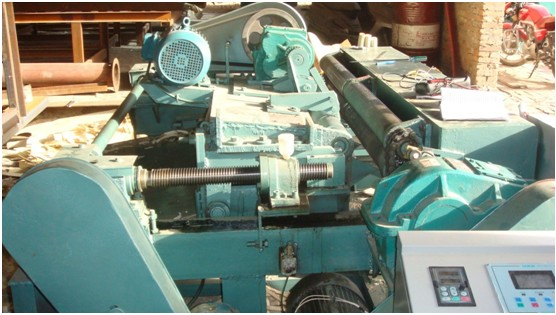

The working principle of the non card rotary cutting machine is shown in the following figure. Logs in a rotary center of the fixed roller and a center of rotation of the mobile roll drive under rotary motion, and the resulting rotary cutting power. Dynamic driving roll center bearing and a rotary cutter is relatively fixed, and move together, such rotary cutter is the sheet metal of the log dig out, and veneer thickness is by dynamic roll and rotary cut blade clearance and rotary cutting knife moving speed control. Dynamic roll and rotary cutting edge clearance is relatively fixed, by adjustment of the machine tool cutting edge gap adjusting device, depending on the rotary cutting plate thickness and rotary cutting knife moving speed through the control system to control the motor speed. Therefore, the movement speed of the rotary cutter is decided by the thickness of the veneer. From Figure 1 we can see that due to the driving roll rotation speed is constant, namely log rotation constant linear velocity, with changes in the diameter of the log and the angular velocity of the log is change, the log rolling a revolution of the time also followed changes, so the rotary cutting knife moving speed is a variable value is a nonlinear relationship. Traditional log centerless rotary cutting machine control is mainly using 2T series electromagnetic VVVF speed regulation method, by using manual control knob or cam curve adjustment change controller input voltage to change the motor speed. The rotary cutting control method of plate thickness error of 1 mm. Therefore, it is very important to design a system that can accurately control the movement speed of the rotary cutting knife to control the thickness of the rotary cutting plate. The basic idea of the system design is: (1) to establish an accurate mathematical model; (2) to take over the original speed control system, to achieve accurate speed control.

The working principle diagram of the non card rotary cutting machine

Three, yichuangfei spinner cutting machine control system

Based on rotary cutting machine principle of work, Wilson is a independent research and development of fly out a set of applicable to currently on the market various types of rotary cutting machine system, after in Shandong, Hebei, Guangxi, Jiangxi and other places of practical application to solve the many machinery manufacturers for rotary cutting CNC equipment and automation. Generally reflect good.

(a) David a spinner cutting machine control system adopts AC80 high performance converter and rotary cutting machine controller. AC80 high performance vector inverter using TI's new generation DSP chip, innovative use of three nuclear design, ultra high speed operation to ensure that the complex vector calculation can be fully realized, the torque response 20ms, steady-state accuracy is less than or equal to 3%. The speed ratio of 1:200, steady-state speed accuracy + 0.2 percent, the rated torque 0.5HZ can output 180 percent.

ECF300 vector inverter application in the rotary cutting machine has the following major technical advantages:

1, for the complex rotation of the object, the starting torque, to ensure that the motor at low speed heavy cutting has a strong cutting force and output uniform. Ensure the smooth and high speed stop and start working.

2, real-time dynamic high-speed operation to ensure rotary cutting thickness is always maintained at a set value, the veneer in normal spiral cut circumstances uniformity error is less than 0.1mm. Good lubrication in some mechanical equipment, the connection process is accurate, can achieve the error of less than 0.05mm.

3, ultra strong deceleration braking ability, to ensure that the knife station immediately stop the requirements.

4, strong adaptability. According to the field characteristic of the rotary cutting machine, the design of the wide range of working voltage. In case of voltage fluctuation to maintain constant output torque, in more than 60 percent of rated voltage can meet the normal operation of rotary cutting. This technology is especially effective for many rural power grid environment.

5, wide speed range adjustable, fast rotating speed, high efficiency, can meet the requirements of the high speed of the board.

(two)yichuangfei the product features of the product features of the rotary cutting machine controller

1, using the rotary encoder as the distance sensor, the measurement accuracy can be increased to 0.01mm;

2, the use of rotary encoder to measure the actual speed of the roller, can avoid errors due to voltage instability caused by the thickness of rotary cutting;

3, the combination of a variety of sensors can be used to choose, whether it is a single encoder or dual encoder and some areas of the electronic ruler can be stable operation; to maximize the use of new and old customers to meet the requirements;

4, the use of high-grade liquid crystal display, full Chinese display, brings a wealth of human-computer interface, real-time display of the working state;

5, a variety of modes of operation, to achieve complete automation and effectively ensure the personal safety of the operator;

6, the built-in switching power supply to make the system more stable, strong anti-interference ability.

Four, the end of the language

Yichuangfei spinner cutting machine control system simplified the traditional rotary cutting machine selection cutting machine structure, eliminating the traditional mechanical equipment due to errors caused by wear and improve the rotary cutting precision. Improve the efficiency of mechanical equipment and the utilization ratio of wood. After a wide range of applications, customers generally reflect good, especially some of the rotary cutting machine equipment more concentrated areas, has formed a certain degree of visibility. So David a spinner cutting machine control system in rotary cutting of humanized design and leading technology products and equipment.