light industry

Application of woodworking machinery - sealing machine.

2016-05-12

First, the foreword

Sealing machine is a kind of woodworking machinery, belonging to wood machinery. Name is used for edge sealing machine use. Applicable to medium density fiber board, blockboard, plywood, particleboard, polymer doors, plywood and other linear edge repair. Can be one-time with double-sided adhesive edge, with the interception of the edge, with a bonding pressing, abreast, chamfering, crude repair, refinement, scraping edge polishing etc. function. Because of its delicate and smooth edge, feel good, straight line closure lubrication. Safe and reliable equipment operation, particularly suitable for the use of furniture, cabinets and other furniture manufacturers to use the plate.

二、Edge type

Edge banding machine according to the functions of the models can be divided as the standard configuration: only have abreast, trimming, scraping, polishing the four main unit. Custom type, customers can double the increase, according to the actual conditions of the slot, such as copying station. The edge woodworking machine according to the control mode mainly manual straight curve edge machine and automatic linear edge banding machine two.

Three, Yi Chong solutions fly automation products in the sealing machine

This solution mainly selects the Yi Fei record company VE124 PLC, touch screen and ECF100 VI10 series inverter system. Using sensors detecting the workpiece so as to complete the edge banding machine conveying -- > glue -- > cut before and after -- > abreast -- > repair side -- > on refinement -- > scraping edge -- > polishing edge banding process. VI10 system touch screen provides a personal computer interface, so that the whole process flow at a glance, the failure of the peripheral circuit can be visualized. ECF100 inverter and PLC MODBUS through the VE124 communication, to facilitate customers to adjust the line speed according to different products. The following is part of the circuit diagram and HMI configuration screen.

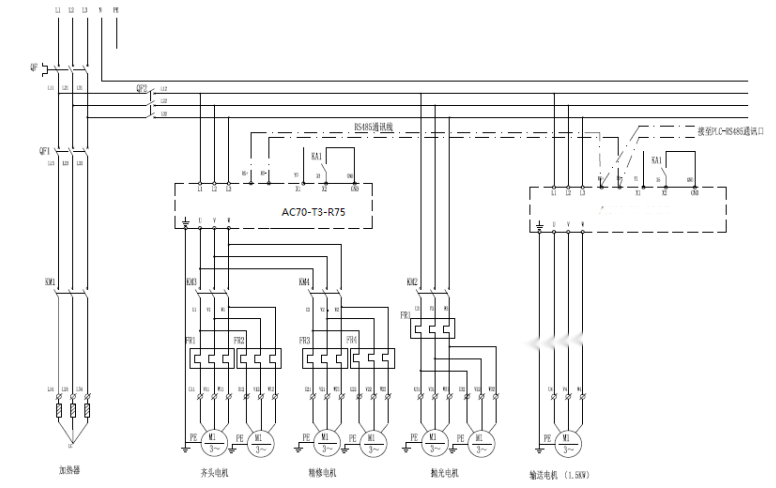

1: the main circuit

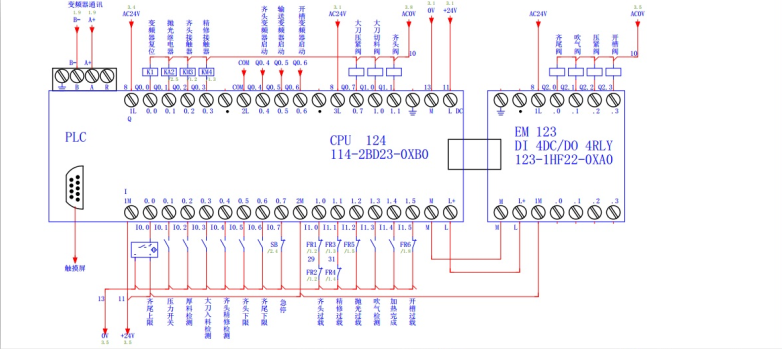

2:PLC I/O电路

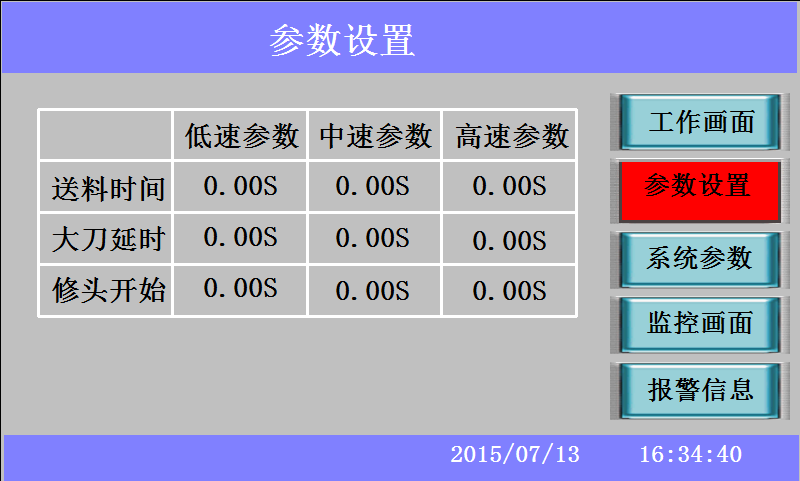

2:HMI configuration screen:

Working picture

Parameter setting screen

Four, debugging method (based on the basic model for example)

1: enter the HMI system parameter page to the temperature control is invalid.

2: adjust the feed on the plate assembly, feeding pressing wheel, pressure wheel, fine repair module, and the polishing wheel adjustment handle.

3: when the mechanical position adjustment probably appropriate location can boot edge test, debugging personnel according to the edge slowly adjust feed on board assembly, feeding pressing wheel, lateral pressure wheel, coarse and fine repair module, and polishing wheel clearance, smooth, rounded edge until can open effective heating mode of the normal production.

Five, inverter parameter settings

|

Function code |

Function name |

Recommended setting |

|

E0.00 |

control mode |

0 |

|

E0.01 |

Run command given channel selection |

1 |

|

E0.02 |

Frequency given master channel selection |

6 |

|

H-66 |

Linkage master station |

0 |

|

H-67 |

Local address |

1-3 |

|

H-68 |

data format |

0 |

|

H-69 |

baud rate |

4 |

Six, the end of the language

Through the actual production test, the customer of Yi chuangfei this whole scheme is very satisfactory. Its advantages are mainly reflected in the following three points

1: have a powerful ability to integrate, PLC, touch screen, frequency converter are Yi Chong Fei products, the customer is not to run around looking for electrical components and busy. 2: strong technical support, we not only provide the hardware, but also provide packages including the preparation of PLC touch screen program, drawing the electrical drawings. 3: quick response service. These are the edge bander manufacturers seize the opportunity to lay the foundation.