light industry

Application of special frequency converter of ECF300 rotary cutting machine in rotary cutting machin

2016-05-12

First, the foreword

Forest resource is scarcity, the timber resources integrated and efficient use of the in front of the pendulum in the woodworking equipment manufacturing industry and wood processing industry has become an important topic. The multilayer board manufacturers in the production process of the single plate, using the traditional have card centering log rotary cutting machine for processing. This processing method has high precision and good quality. However, due to the heart card, the rotary cutting diameter logs in a 200 mm, will not be able to card peeling machine; and log with small diameter log reduction in stiffness, rotary cut veneer quality is poor, then if the remaining wood core abandoned or processed into wood core plate will lead to great waste of raw materials, thereby increasing the production cost of the single board. So manufacturers generally use non card log rotary cutting machine for the remaining wood core again rotary cutting, make the full use of raw materials.

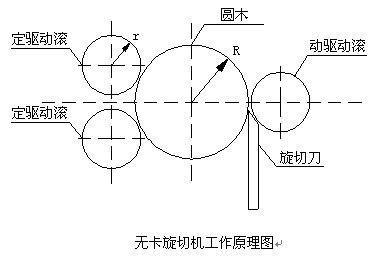

二、The working principle of round cutting machine

The working principle of the non card rotary cutting machine is shown in the following figure. Logs in a rotary center of the fixed roller and a center of rotation of the mobile roll drive under rotary motion, and the resulting rotary cutting power. Driving dynamic roll center bearing and a rotary cutter is relatively fixed, and move together, such rotary cutter is the sheet metal of the log dig out, and veneer thickness is by dynamic roll and rotary cut blade clearance and rotary cutting knife moving speed control, dynamic roll and rotary cutting edge clearance is relatively fixed, by adjustment of the machine tool cutting edge gap adjusting device, depending on the rotary cutting plate thickness and rotary cutting the moving speed of the cutter through the control system controls the driving motor speed, so the rotary cutting knife moving speed also indirectly determines the thickness of the veneer. From Figure 1 it can be seen, due to the driving roll rotation speed is constant, namely log rotation constant linear velocity, with changes in the diameter of the log and the angular velocity of the log is change, the log rolling a revolution of the time also followed changes, so the rotary cutting knife moving speed is a variable value is a nonlinear relationship. Centerless traditional log rotary cutting machine is controlled primarily by 2T series electromagnetic VVVF speed control method by using manual control knob or cam curve adjustment change controller input voltage to change the motor speed. The rotary cutting control method of plate thickness error of 1mm. Therefore, it is very important to design a system that can accurately control the movement speed of the rotary cutting knife to control the thickness of the rotary cutting plate. The basic idea of system design is:

(1) to establish an accurate mathematical model;

(2) to take over the original speed control system, to achieve accurate speed control.

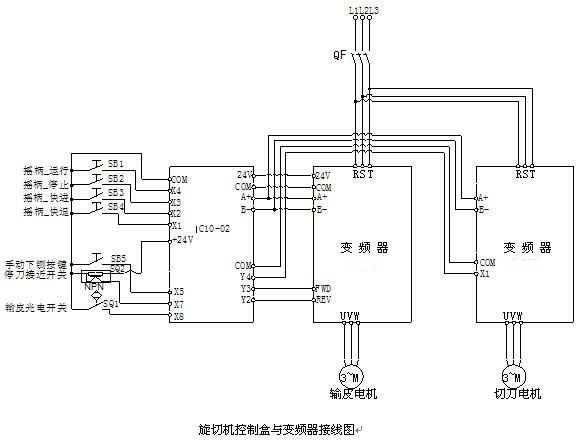

Three, Yi chuangfei ECF300 rotary cutting machine special inverter and the advantages of a spinner control box Wilson cut product special machine instructions

1, the microcomputer as the core of the whole digital control system;

2, the use of advanced algorithm and compensation mode, so that the thickness of the wood cut out of uniform, accurate and complete;

3, using the rotary encoder as the distance sensor, the measurement accuracy can be increased to 0.01 mm;

4, the use of rotary encoder to measure the actual speed of the roller, can avoid errors due to voltage instability caused by the thickness of rotary cutting;

5, set the state of the finger touch type, two paragraph type, automatic acceleration mode, increase / decrease the way, make the set value more relaxed;

6, the use of high-grade 128*64 LCD display, full Chinese character display, so that the operation is more convenient;

7, the frequency can be given through the RS485 communication, so that the frequency of a given error is greatly reduced;

8, a variety of use mode, can realize the process automation and effectively ensure the personal safety of the operator;

9, a variety of sensor combination model can be used to choose, to the greatest extent to meet the new and old customers to use requirements;

10, real-time monitoring of the roller rotation direction, such as reverse parking alarm immediately to reduce the losses;

11, whether or not in a state of swing can easily adjust the cutting thickness;

12, power down can not continue to work, greatly facilitate the use of;

13, built-in card, no card rotary cutting machine two control schemes.

yichuangfei ECF300 rotary cutting machine special inverter and David a spinner cutting machine with the use of special control box. Through the encoder for real-time detection of the diameter of the log, the drive roll and rotary cutter speed are calculated, confirming the real-time output frequency of inverter. By changing the driving roll and rotary cutter speed follow log diameter variation, which makes the rotary cutting thickness is always maintained at a set value, and the deviation was less than + 1%. When the diameter of the log reaches a set minimum, automatic back driven roll and rotary cutting knives, fundamentally put an end to the dynamic drive roll and rotary cutting knife caused by operation with fixed drive roll collision and maximize cutting logs, docking at the same time.

Four, summary

Yi Chuang Fei rotation of the ECF300 a spinner cutting machine special control box to simplify the traditional rotary cutting machine mechanical structure incised machine dedicated inverter with Wilson, eliminating the traditional mechanical equipment due to errors caused by wear and improve the rotary cutting precision. Improve the efficiency of mechanical equipment and the utilization ratio of wood.