light industry

Application of ECF100 inverter in the leather cutting machine.

2016-05-12

I. Introduction

The traditional leather cutting machine with manual control, manual operation by measuring length of leather workers, under the manual. There are defects of high labor cost, operational risk, low precision, slow speed and so on. Machinery manufacturers and the users are looking for a new type of leather cutting machine automatic control to replace the traditional leather cutting machine.

Two, technical program

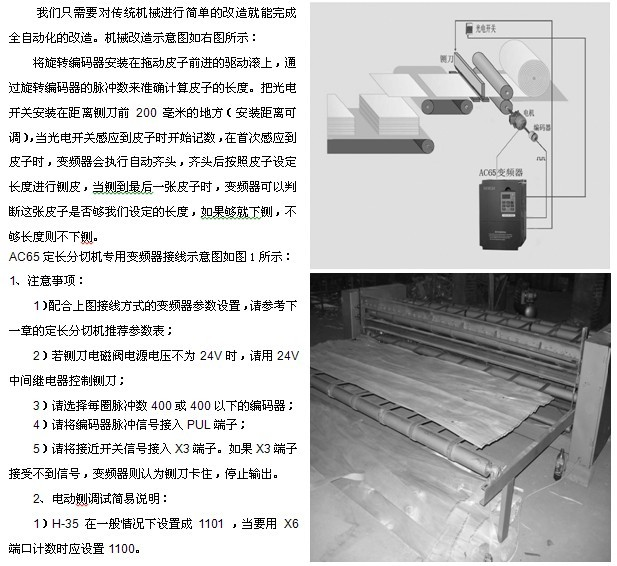

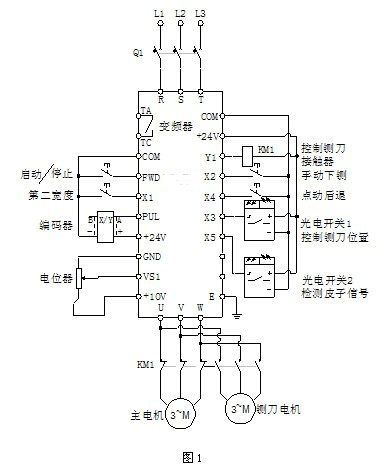

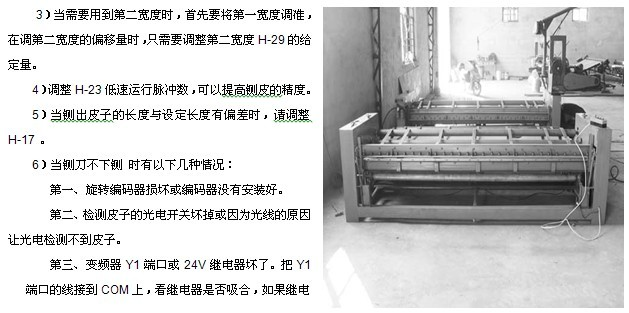

Through the long-term study of leather cutting machine working mode, we developed a leather cutting machine special inverter device type AC65. AC65 set long slitting machine dedicated inverter built-in the slitter special program, can automatically identify the leather length, cutting leather precision, to ensure that the four edges of the plate products neat and orderly. Automatic control of the blade. Automatic detection of whether there is no parking or leather, automatic alarm, and remind workers heavy leather. At the same time, can realize the automatic block automatic tail and automatic skin function.

三、方案实施

2) when the frequency converter SC, please do not reset and restart. Should first open the motor line, see the inverter in the case of the motor without the normal operation, such as the normal operation, please carefully check the motor and motor line.

Do not pull, so bad and bad relay, frequency converter.

7) when it will not send the leather. The following two conditions:

First, the speed potentiometer twist to 0.

Second photoelectric switches, control guillotine broken position.

8) F-12 can speed adjustment motor.

9) H-20, H-33, H-37, H-35, H-35, H-36, H-34 of the time can improve the work efficiency.

Four, frequency converter parameters set

|

Serial number |

Function description |

Recommended setting |

|

E-01 |

Run command given channel selection |

1 |

|

E-02 |

Frequency given master channel selection |

2 |

|

E-13 |

Acceleration time 1 |

0.2second |

|

E-14 |

Deceleration time 1 |

0.2second |

|

E-11 |

lower rate limit |

0.00Hz |

|

E-13 |

Acceleration time 1 |

0.2second |

|

E-14 |

Deceleration time 1 |

0.2second |

|

F-01 |

Input signal selection 1 (X1) |

29: second width |

|

F-02 |

Input signal selection 2 (X2) |

28:Hand down signal |

|

F-03 |

Input signal selection 3 (X3) |

21:Under the motor stop signal. |

|

F-04 |

Input signal selection 4 (X4) |

2:Reverse jog operation |

|

F-05 |

Input signal selection 5 (X5) |

26:Photoelectric switch signal |

|

F-10 |

Low speed frequency before knife |

10.00Hz |

|

F-11 |

Idle frequency |

20.00Hz |

|

F-12 |

Guillotine operation frequency |

45.00Hz |

|

F-31 |

Output terminal Y1 |

13:Under the signal. |

|

H-12 |

Encoder pulse number |

According to the number of pulses per turn of the encoder |

|

H-12 |

Encoder pulse number |

According to the number of pulses per turn of the encoder |

|

H-13 |

Shaft diameter |

According to the actual diameter of the roller set |

|

H-14 |

Shaft gear ratio |

1 |

|

H-16 |

Leather cutting length setting |

According to the user set length cut leather(Keyboard available‘△’‘▽’To adjust) |

|

H-20 |

Switch 2 after delay |

0.12 |

|

H-23 |

Low speed operating pulse |

400 |

|

H-33 |

Switch to the 1 frontier |

0.20s |

|

H-34 |

Switch 1 after delay |

0.20s |

|

H-35 |

Under the control. |

1101 |

|

H-36 |

Switch to the 2 Frontier |

0.5second |

|

H-37 |

Time stop time |

0.2second |

|

H-38 |

Leather cutting machine cavity length |

300 mm (according to the maximum diameter of the hole or set) |

Five, the end of the language

It can be seen from the transformation of the way, the transformation of low cost, simple transformation, simple control method. Through the customer's field testing and long-term use, the product has high processing precision, the unit time production is 4 times of the traditional way, and the equipment cost is low, the maintenance is convenient, safe and reliable. Can be very good to improve

The user's economic benefits, quick, worth promoting.