light industry

Application of industrial control products in extruder

2016-05-12

First, the foreword

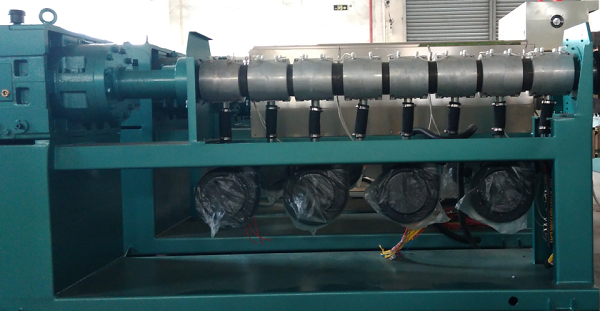

Extruder is a widely used equipment in the plastic processing machinery. The work flow is: through the filling machine for solid material filling, solid material conveying, fusion segregation, melt conveying finally through the mold forming. According to the extrusion actuator and screw and screw. This paper mainly introduces the Yi chuangfei industrial products especially extrusion special temperature control module in the screw extrusion machine for the excellent performance. The picture below is a device scene.

Heating extrusion part:

Extrusion traction part:

Two, the shortcomings of the original control method

Field equipment to take the 6 step by step heating method to meet the lamp, wire, wire and other products processing requirements. The whole production process of the temperature rising speed, constant temperature, temperature overshoot range control, proportional speed peripheral auxiliary equipment require very precise. Through the analysis and summary of the field equipment working condition and the original control mode, the following disadvantages:

1: the original control in temperature control of the temperature control module, high cost, control is not flexible, and the temperature control is not ideal, mainly: temperature rise for a long time, overshoot range, constant temperature effect is not good.

2: speed control mode the analog volume control mode, and analog module there is always the problem resolution, so in geometric speed will exist certain errors, so in several machines with traction extrusion material will cause pull the uneven material, cutting, or in a workshop section pile material problem.

Three, Yi chuangfei solutions

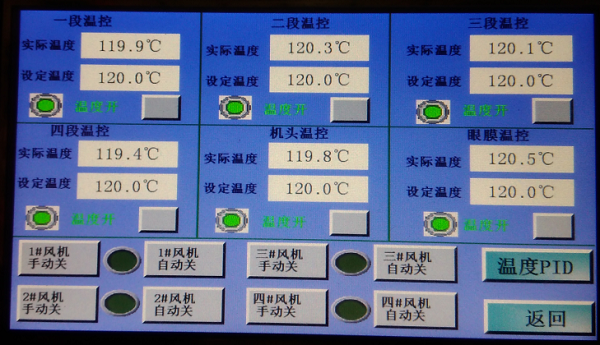

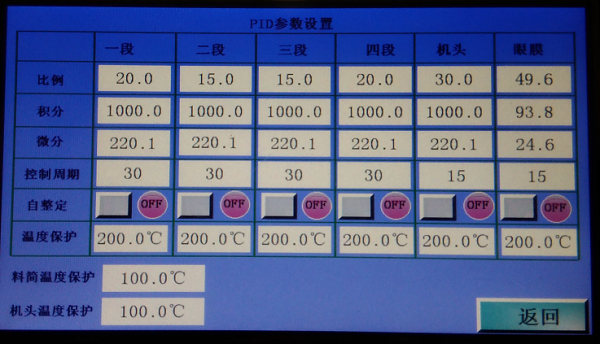

Main control part adopts Yi Chong Fei ECF200 series of PLC plus analog input module (module for extrusion industry-specific, acquisition resolution higher than similar products in the industry), complete the precise control of paragraph 6 of the heating element, the precision reach plus or minus 0-1 degrees, module robust self-tuning capability makes the control system more simple and flexible. Geometric synchronous speed drive components by Yi Chong Fei ECF300 series inverter, logic part of the ECF200 CPU internal powerful floating-point computation ability, speed error control in less than 0.01Hz and frequency to rule by Yi a fly industrial products strong networking ability to complete, without additional hardware. Touch screen using VI10 series touch screen to facilitate the modification of parameters, running status monitoring.

Touch screen temperature control screen:

PID parameters adjustment screen:

Four, Yi chuangfei system solution advantage

1, temperature control operation is stable, no need to add other auxiliary equipment, the temperature control mode is flexible, the user can choose according to their own process. Because the temperature rise time, overshoot and other aspects of control is very good, so the energy saving and environmental protection, but also improve the work efficiency.

2, and a speed control precision, small error, use Yi Chong Fei industrial products of internal communication protocol can be completed on the velocity of the geometric control, without adding other elements, simple wiring reduces the hardware contact fault.

3, the composition of the whole system all adopt Yi Fei record company of industrial products, so the system is compatible with stable, technical support and spare parts purchase, very convenience.