light industry

Application of frequency converter in pulp dyeing machine

2016-05-12

Pulp dyeing machine including the sizing and dyeing function used in textile industry, weaving preparation engineering, complete the sizing process. While adapting to the shuttle and shuttleless loom supporting requirements, meet the starch, chemical pulp and mixed slurry of staple cotton, hemp, and mixed fabric, chemical fiber and blended fabric of warp sizing. Adapting high-density and requirements in species of the sizing technology fine wide all kinds of fabric, fabric cotton textile factory development and production of high output and high benefit species indispensable key equipment.

Two, ASLGA389 type dyeing pulp combined machine

(1) beam size: maximum diameter of 1000mm, adapt to the width of 1800mm.

(2) weaving shaft size: maximum winding diameter 800mm, the maximum length of the shaft tube of 2760mm beam.

(3) creel number: 4 = 16.

(4) speed: 2 ~ 60m/min.

(5) snail speed: 0.5m/min.

Three, the composition of the pulp dyeing machine

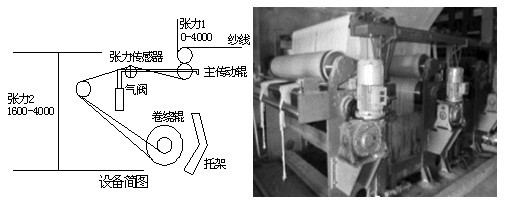

Pulp dyeing machine, dyeing by creel, drying room, yarn storage rack, slurry tank, wet split, front part. The following diagram of equipment:

Four, the application of frequency converter

1, the whole machine tension regulation:

Overall transmission: the main electrode is 11kW, 4 pole frequency conversion motor, frequency conversion speed regulation. The car side shaft universal coupling.

(1) the yarn guide roller is adjusted by the XP1 stepless speed changer.

(2) by creel 5 locomotives with 1 P4 stepless regulator.

(3) out of the dyeing tank (3 washing rolling car) with 1 sets of P4 stepless speed changer regulation.

(4) the last 1 sets of rolling mill and dyeing bake room between the use of 1 sets of XP1 stepless speed changer adjustment.

2, the control of the winding shaft

The Yi Chong Fei ECF200-22kW inverter and 22KW frequency conversion motor, by 1:1.3 belt wheel drive the winding roller; PLC to control the whole machine program and action. Tension roller and tension detector.

(1) Zhang Ligun is given by the cylinder pressure (CYLINDER 0.15 ~ 0.63Mpa);

(2) tension sensor output 0 ~ 10V signal (PW70d/AIP65 Type 360 degrees 2571 degrees 1%);

Five, summary

Previously, most of the introduction of such equipment, most of the DC speed control and mechanical stepless speed change device. In recent years, the use of variable frequency speed control for the user to accept. We tested the transformation of the frequency control sizing machine, and achieved satisfactory results.