light industry

Application of frequency converter in the 300 meter high speed coating machine

2016-05-12

1, overview

Coating industry and paper industry with its driving point, high demand for high, continuous production characteristics, together with the metallurgical industry known as the highest automatic control requirements of the industry. With the development of power electronic technology, AC drive system in paper industry is applied more and more widely, high performance, vector control inverter, makes the past need is realized by a DC double closed loop system transmission control can be accomplished by the AC drive system. In order to meet the needs of different types of paper production and the need to improve the labor productivity, paper-making production line to develop towards the direction of high speed and full automation, industrial controller (PLC) and field bus more and more application in papermaking industry.

My company in the paper machine drive through many years of practice, has a wealth of experience. Vector control inverter and PLC is composed of fieldbus control system, the perfect realization of the entire production line control. The system has many advantages, response time, wiring, less failure rate is low, maintenance Small and convenient maintenance, so that save money, but also reduce the labor intensity of the workers.

2, project overview

(1) design basis

In the premise of ensure the technical specification book relevant technical requirements, we play the advantages of its software (user program) design, using advanced and mature of power electronics, suite, integrate and optimize the configuration, to provide the electrical control system can not only fully meet the paper machine normal continuous production process of the proposed requirements, and under the prerequisite of guaranteeing the precision control, with high stability, high reliability, convenient operation and easy maintenance, etc..

Power supply: three-phase four wire AC

Power supply voltage: 380VAC/50Hz

Voltage change: + 10%

Frequency variation: + 2%

Phase imbalance: + 2%

Torque change: + 20%

The temperature range of ~40 DEG C: 0

Balance is relatively modest: 90%

Altitude: <1000M

(2) paper machine technical data

Paper thermal paper

Paper quantitative 40~60g/m22

Paper width 1400mm

Roll width 1600mm

7% humidity paper

Working speed 250m/min

Design speed 300m/min

Balance speed 350m/min

Crawling speed 20m/min

Supply voltage V/Hz 380/50

Control voltage V/Hz 220/50

Control voltage 24VDC

Compressed air pressure 0.6 MPa

Dryer steam pressure < 0.7 MPa

Total installed capacity kw

A section of coating amount g/m2 5~8

A solid content of 45~50%

Two section coating amount g/m2 3~5

Two solid content 25~30%

Overall arrangement mode to be determined

Product paint color by the customer to provide color

(3) parameters of main drive of paper machine

Paper rotary 2.2KW auxiliary paper back driving point

The auxiliary roller 4KW auxiliary back paper transmission point

The main drive of the back roller 7.5KWx2

Coating roller 1.5KWx2 auxiliary drive point

5.5KW with 500 traction rollers and main drive

Back coated roller 4kw main drive

11KW master drive

The main drive of two roll calender roller 7.5KW

Roll paper transmission 5.5KW main drive

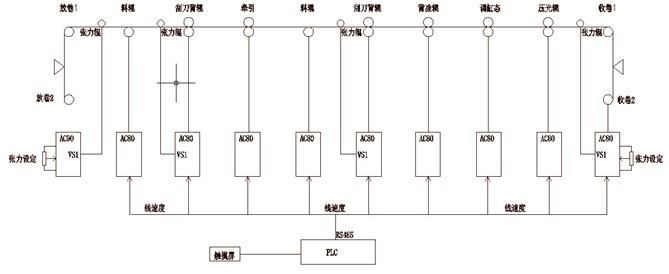

3, system program

(1) transmission mode: All Digital AC frequency conversion speed regulation

(2) control mode: two level control system

2.1 first level: the use of Wei Chong company AC80B series of high performance vector frequency conversion structure: into the line cabinet, frequency conversion cabinet

2.1.1 into the line cabinet

L circuit breaker adopts frame type, three off protection

L line: a forward line, bus connection

L implementation of frequency conversion unit and power grid isolation, protection, grounding

L system: circuit breaker, common control circuit, current and voltage detection, copper busbar etc..

L protection level: IP20

2.1.2 frequency conversion cabinet

L through the circuit breaker and AC busbar connected AC bus AC modulated frequency can be adjustable and controllable three-phase alternating current, then drive AC motor to adjust the running

L speed feedback template: the use of pulse detector to measure the speed of the motor, the signal through the speed feedback after the conversion of the template, the input converter, the speed of the closed-loop control

L communication interface: the built-in MODBUS module, and the PLC control system in MODBUS mode for communication

L system is composed of frequency converter, communication module, speed feedback module, circuit breaker, motor fan power supply, protection and other equipment.

2.1.3 control task

Speed closed-loop control, torque control, current control, start up link, over flow pressure protection control, process control, fault detection and protection, etc..

Second level 2.2: PLC control center, operating table

2.21PLC

L S7-200 SIEMENS series of cpu226 can be programmed for the control of frequency conversion unit, the use of PLC given the main speed +PID control mode, better control of the tension and speed of the coating.

L PLC as master station, frequency converter as slave station, mainly to achieve control of the inverter starting, stopping, crawling, operation, edged up, down, speed chain and load distribution function

L the main task: communication control, speed synchronization control, start / stop, crawling / operation control, edged up / down control, single action, linkage, punctuality, counter point control, torque distribution control, tension control, linkage control and machine control

L system structure: CPU226, control power supply, etc.

2.2.2 operating table:

L style: bevel type

L operating table is equipped with emergency stop switch, which is used for emergency shutdown.

L control function: stop, crawling, running, edged, slightly taut,

L system functions: emergency stop button, boot button, etc.

(3) system introduction

Processing of paper production technology development and coated paper processing equipment update, in the coating process the detection and control of that run paper tension in the production equipment is to improve the product quality and yield is an important technical measures. So in the control of the mechanical and electrical properties of the coating machine, the key is to control the tension of the coating machine system. Because of the size of the tension directly affects the quality and quantity of products: tension is too large, will destroy the physical properties of the coated paper, paper influence the service life and quality; tension is too small, are too loose, paper is not smooth, will affect the follow-up process, and the quality of products.

Unwinding the AC90 unwinding special open loop vector inverter independent control, automatic tracking the tension of the paper processing, and automatic roll changing, control rolling speed, keep constant tension, save the previous tedious pendulum rod mechanism, making put bodies roll more simple, so as to save the cost. (this part is outside the Association)

Intermediate processing links at all levels by AC80B open-loop high performance vector frequency converter, control mode is the main signal and fine tune the signal control linkage ratio are set according to the proportion of superposition; in the middle of the applicator driven the main and auxiliary frequency superposition method (main frequency PID tuning) control, greatly increased synchronization precision.

When the volume of the winding is changed, the range of the coil diameter is larger, the torque variation range is large, and the torque required for the minimum torque is very small. Although the AC90 series inverter can achieve tension open-loop control, but because of the torque control is not high, it is difficult to achieve low torque control, speed mode can be used under tension closed loop control. Therefore, the volume selection of AC90 dedicated open loop vector inverter. AC90 output frequency f = f main +fPID, synchronous speed feedforward, PID (ID to fine tune the output volume), instruction frequency output by PID adjusting amount and speed feedforward overlay and, avoid caused due to the large variation range of torque is not easy to control the situation.

(4) system advantage

1, by frequency inverter to complete the levels of tension control, tension control using tension sensor, system is simple and stable, levels of tension control by frequency converter, greatly reduce the difficulty of the manufacturers work, closed loop tension and AC90 AC80B control modes can even achieve complete stabilization of the tension in the process of acceleration and deceleration, with PLC and synchronous controller to control the driving and frequency converter speed. At the same time as the other inverter speed signal line.

2, ECF200 closed loop tension control easy to achieve acceleration and deceleration process of constant tension, coupled with the installation of tension roll, and high precision control to ensure that the coating effect is highly uniform.

3, double station reeling with pre driven lifting function and the tension function, can meet the high-speed non-stop automatic roll changing, the demand of improving the production efficiency. Taper control can be conveniently and accurately control taper tension. The winding effect is better, and accurate receiving volume control can avoid flowering Chinese cabbage type side winding, the winding effect is better.

4, whole system mainly driving part are used for main and auxiliary frequency superposition method (main frequency PID tuning) of control, greatly increases the synchronization precision, avoid the cumulative error caused by high-speed mechanical and jumbo rewinding operation occurred unpredictable situation.

4, accuracy index

Speed control:

Static accuracy: less than 0.01%; the dynamic accuracy: less than 0.05%

Relevant conditions:

L mechanical equipment: in good condition, normal operation;

L feedback form: photoelectric encoder feedback;

L AC motor: general induction motor (preferably variable frequency motor)

L given way: all digital communication given

L control mode: speed closed loop control

L load fluctuation: no more than + 20%

L power grid fluctuation: 380V + 10%

L long term load ratio: <90%

L operating frequency: >10Hz

L minimum load: >1/8 converter rated load

L environment temperature: 0 ~40 DEG C

L power grid frequency range: 50Hz + 3%

L motor operating mode: constant torque

Load control:

Static accuracy: + 1%; dynamic accuracy: + 3%

Conditions: tension detection accuracy, the paper sheet and roll surface no relative slip.

Overload capacity:

150%/60S

Static accuracy: the amount of change at a given speed for 24 hours.

Dynamic accuracy: the change of mechanical inertia and friction in the process of speed or speed reduction

System technical index:

L a given resolution: 0.001Hz

L speed regulation range ratio: >1 ~ 10%

L speed up time: 0 ~ 600S

5, security level

According to the DIN40050/IEC144 standard, the door and the side of IP41, the top and bottom cabinet is IP00, operation table for IP56.

6, system characteristics

L convenient installation: due to the adoption of the Modbus communication, the console to control room cable is greatly reduced, all the signals in the transmission mainly through two conductor shielded twisted pair to complete, therefore, the installation is simple, can greatly shorten the duration for installation and debugging.

L all digital communication: high precision, good anti-interference

L easy maintenance: because PLC and frequency converter are high reliability, and is modular products, even failure, replacement is also very convenient, fault recovery period is short

7, function settings

7.1 speed general given

Using direct digital line speed for a given to a coating device driver as the first main transfer point, the speed is given as a whole paper machine is always given, transmission speed with the point of the speed change and change, and taking the opportunity based speed chain is established according to the process of paper machine, given in the operation panel design special general given picture.

7.2 start stop control

Control the driving point of each drive down, only to their own division, the drive group for independent control, does not affect other transmission points. And in order to reduce the impact of when the equipment stops, in starting process is also provided with a s curve process, speed according to the given speed rising curve increases the speed, and speed loop and current loop blockade signal cancellation, put into operation; when the operator press the stop button, equipment can be in a free parking, but also according to the given decline curve parking, after the arrival of the zero speed speed loop and current loop blockade, to prevent misoperation.

7.3 crawl / run control

When the equipment maintenance, the paper cited before the preheating of the dryer and washing equipment and system requirements for low speed operation, when everything was normal after the switch to high-speed operation. Creeping crawling position, paper machine is in accordance with the crawling speed, crawl speed generally 20 ~ 30m / min speed; when the cited paper, the switching to the operation position switches, paper machine according to the given speed operation, this paper machine will automatically switch from the crawling speed to speed, crawling and running speed between changes in system in accordance with the S curve time action

7.4 speed adjustment control

According to the requirements of the process, speed between each segment difference need to maintain a certain speed, and the production for different types of paper speed difference is also different, edged, micro drop is used for various segments of the speed adjustment, speed the driving point between the front and rear differential can meet the requirements of production process. Fine tuning range is generally designed in + 10% ~ + 15% (relative to a given speed), in the range to meet the requirements of the vast majority of systems, special circumstances can be carried out in the field of specific adjustments. After adjusting the speed difference with memory function, can automatically call the last stop is adjusted well speed difference in the next boot.

7.5 point move (positive and negative)

For convenient maintenance, cleaning off paper, cloth or paper rope set set of circumstances, need equipment for rotating an angle. In this case, when the button is pressed, the device stops running when the device is operated according to the point of the point, and the device stops running when the point is released.

7.6 emergency stop

Mainly used to deal with emergencies in the whole line of parking. When the button is pressed, the paper machine is cut off and the main power source of the transmission system is cut off. In order to protect the equipment and personal safety.

7.7 torque control (load distribution)

In paper machine part, press department and other department is usually a main auxiliary transmission group, that the load of a device by multiple motors shared, so between the groups of transmission, that is, to maintain a stable individual transmission speed, still have to ensure that each transmission sharing the load evenly, so as to ensure the whole transmission group work, otherwise it will happen is drag and motor work in generating state caused by DC circuit voltage increases, the work on the electric motor superabundant overload and burn the inverter, also the equipment adverse also, serious will damage. So according to the relationship between each gearing transmission between groups, usually set up a main transmission, use it to control the speed and the rest of the transmission as auxiliary transmission, the of load distribution, all according to a certain proportion of share the load.

7.8 tension function

In some open paper machine of the cited paper, due to the distance between the front and the back of larger, in the cited paper may page drop is bigger, normal operation is by edged up after a point speed lets page straightened and the micro drop speed adjusted back to the original speed, such operations is very complicated and long period of adjustment and easy to change the original synchronization characteristics. Through the tension function can be a good solution to this problem. When holding tight button, fast speed will have a rapid increase in the original basis, the paper quickly straightened. Loosen the tension button when the speed back to the original speed, so that it can easily lead to the operation of the paper, but do not change the original synchronization.

7.9 tension control

In some segments of the paper machine, it is not only to ensure that the paper has a certain tension, but also can not be broken; so in this system on the three drying and roll paper tension control. The tension signal (indirect tension or direct tension) in the PLC, so as to achieve closed-loop tension control, to ensure good quality of operation, reduce broken paper, improve the rate of paper.

7.10 auxiliary chain control

Coating machine with various auxiliary control, different auxiliaries require different operating conditions. In order to ensure the auxiliary machine and paper machine of chain operation, usually in the main drive part of the expanded PLC interface module to achieve mutual linkage.

8, system unit equipment

8.1 AC80B series inverter

The biggest advantage of AC80B series transmission products is that the same control technology is used in the whole power range.

The core technology of AC80B L is direct torque control (DTC). It is the most advanced control mode of AC asynchronous motor. DTC stable and outstanding performance, so that the AC80B transmission products applied to a variety of industrial areas.

L Wei Chong AC drive continuous improvement in the user interface. Startup wizard application, so that the debugging of AC80B is very simple.

L pulse encoder module does not increase the volume, there is no need to use a wire connection.

L low noise cooling fan function and excellent heat dissipation and three circuit board.

8.2 200MODBUS S7 features and system composition

S7 - 226 as the second level system, it is the center of the whole control system, mainly used for field devices running status monitoring, data acquisition and processing, speed chain control, crawling / operation control, communication control, electrical equipment switch control and parameter adjustment to realize the system control function.

-226 S7 control station of the central processing module uses the most advanced computer technology and electronic integrated circuit, the module is small, but powerful, is the ideal product of small and medium system. Through the serial port and the computer connected with Step7 can be programmed, debugged, diagnosis and so on, through the MODBUS interface can be connected with the support of this protocol from the station to form a fieldbus control network. As the main station can be connected to the drive and the field operating table HMT equipment, to achieve the relevant control.

8.3 operation panel

Using micro lundgaard performance touch screen as the user operation interface and convenient control and operation of the user, provide a rich graphical, full Chinese interface, easy to use, providing an enormous amount of information.