light industry

Application of ECF500T Series in high efficiency steam engine

2016-05-12

First, the foreword

Efficient decatizing machine. It is used in natural wool, hemp, cotton, silk and its blended knitted and woven fabric shaping and finishing, after the equipment after finishing the fabric with: dimensional stability, feel is smooth, soft, mild luster and characteristics.

High efficiency steam machine main controller is completed by programmable logic controller (PLC), complete speed and tension setting, frequency converter parameter setting, import and export logic control, etc.. According to the parameters of the frequency converter and the given speed and tension automatic operation, so that the fabric to obtain a high quality of the effect of steam.

Two, working principle and its characteristics

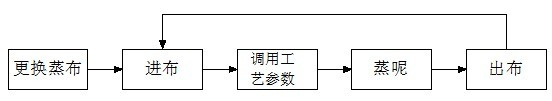

Replace steam cloth: in order to ensure the stability of the steam distribution process, about half a year to replace the steam cloth. It is required that the steam roller and the storage cloth roll can be replaced separately.

In the whole process of the cloth and the cloth, the tension is stable, and the tension of the cloth and the cloth can be adjusted separately. Into the cloth and cloth switching, require the drive torque / speed can be freely switch, tension control, tension accuracy requirements of control in the + 5%, speed control requirements of precision velocity control in + 1%, and according to the speed sensor on line speed is adjusted in real time.

We do a variety of process parameters in the PLC, to facilitate the customer directly call.

High efficiency steam machine mainly has the following characteristics:

1, it is not easy to damp cloth steaming. Mainly adopted three measures:

A: in the process of performing automatic steaming, the first implementation of the program is the automatic discharge of condensate in the external pipeline. (the purpose is not to allow the condensate water inside the external pipe to enter the steam roller)

B: when the steam into the steam roller, due to be processed fabric, lining, steam and wall temperature than steam temperature low decating, so steam cold to hot and cold replacement, then steamed and within the backlog of a large number of condensation water, if not promptly discharge, condensation of water and steam and penetration to the vapor interlining and fabric to be processed fabric watermark is generated, and the function enable backlog in the steam and the condensed water nozzle from introverted outside intermittent discharge.

C: when the machine is in a cloth, the program automatically opens drying and steam valve, the persistence on the lining cloth moisture by baking and drying.

2, then steamed lining can not deviate (machines are equipped with a photoelectric automatic device), the biggest characteristic of the device is as long as to the accused of the fabric is within the control range, it can make correction and is always in the middle position (horizontal position detecting device.

3, import and export operation is simple. To complete the operation of the forward, backward, stop, up and down speed by simply manipulating an operating lever.

4, decatizing tension can be set according to the technological requirements of interlining.

5, steam it has manual and automatic two ways of working (optional):

A: manual operation can be achieved in the steam, outside the steam, pumping three kinds of working state, touch screen simulation instrument shows the actual working hours.

B: automatic operation by variable program controller (PLC) control

The machine has set seven steam:

A mode (from the inside out) can be stored in a total of 5 different processes

B (by outward processing) can be stored in a total of 5 different processes

5 different processes can be stored in the C mode (from inside to outside).

D mode (from the outward outward processing) can be stored in a total of 5 different processes

E mode (from the inside out to the outside processing) can be stored in a total of 5 different processes

F mode (from the outside to the inside and outside processing) can be stored in a total of 5 different processes

1-2 kind of technology can be stored under the G mode (new steam distribution).

6, the replacement of decating lining on the conveyor belt can be directly out of cloth, no longer need to rely on manpower to pull out the cloth.

7, the machine can be equipped with a special steam compensating device (optional part), its biggest advantage is: processing of synthetic fabrics increased steam temperature decatizing fabric shaping effect is better.

8, the machine also added a new set of internal and external compensation of the new device, the device can make the inner layer and outer layer temperature consistent, so that the real solution to the steam generated after the match and color does not match.

9, PLC, touch screen, frequency converter, a tension sensor composed of a set of advanced control system, touch screen to design rich interface, operate the touchscreen can be conveniently and procedure of various process parameters were selected, set, adjust and change, so as to obtain the best decating effect. The random operation can be easily observed by the touch screen.

10, the establishment of a perfect safety protection device, and a fault diagnosis system and alarm system, through the touch screen can diagnose the fault, fault location, and processing method. PLC for all process parameters and procedures to achieve full automatic control.

11, in order to correct diagnosis and analysis of product quality is not caused by human activity, especially, the night shift in the unsupervised case that the operator is to strictly according to the automatic process to operate. Therefore, the system can for violation of operation of the technology for real-time recording, storage and analysis of relevant personnel, provide the basis for assessment.

Three, the end of the language

Yi Chong fly ECF500T is tension control of winding demand for textile, printing, film and other industry needs and the design of specific frequency converter, the excellent torque control precision, precise roll diameter calculation function, perfect taper control makes AC90 in tension winding industry received one of the users from.