light industry

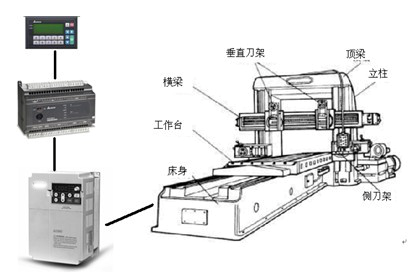

yichuangfei The application of ECF200 converter in B210A on the transformation of Longmen planer

2016-05-12

1, preface

B2010a model planer main points for mechanical and electrical control of two major components, mechanical part is relatively stable, and make planer running in optimal state depends on electrical control system control mode. In the traditional gantry planer, the mechanical part of the utility model is good in rigidity, high accuracy, general the basic performance can reach the level of modern similar mechanical, but control and driving part is different degree of aging, the transformation of old double housing planer has great practical significance.

Yi Fei record of ECF200 series inverter by TI's new generation of high-speed motor control special DSP, and innovative use of three nuclear processing platform technology. Ultra high speed operation to ensure the complete implementation of the complex vector computing; a new generation of non PG vector control, the use of advanced motor model algorithm, so that open loop torque control to achieve closed-loop algorithm. Torque response 10ms, steady state accuracy < =5%. Speed ratio of up to 1:200, steady-state speed accuracy of 0.2%. Hz can output 180% rated torque; vector control PG, Hz can output 180% of the rated torque, steady speed precision can reach 0.02%, the dynamic response time < 10ms; a full range of over-current, over-voltage, overload and inhibiting stall prevent functional; improve the power on self-test function, wide range voltage design; take the lead in the use of a new generation of Infineon IGBT module, higher reliability.

2, Longmen planer electrical control the overall requirements

A) cancel the motor expanding machine, generator, in order to reduce noise, overcome many control defects.

B) work table can realize automatic cycle work and point move, can adjust the working table speed, smooth commutation, and have automatic and the limit protection of work time.

C) the vertical turret can be conveniently in the horizontal and vertical two direction fast moving and feed, and can move quickly and automatically enters the switch.

D) around the side of the turret in the upper and lower direction of fast moving and feed, can carry out fast shift / automatic switch. And the left and right side of the knife knife limit switch to prevent its upward movement when the collision with the beam.

E) beams can be easily moved up and down and clamping to relax, to adjust the degree of adjustment; the beam down when there is a rebound delay, delay time adjustable.

F) continuous / automatic switch for the lubrication pump, Yide electrical system, oil pump is oil, to a certain pressure, oil pressure relay contact is closed, workbench.

G) has the protection link control, guaranteed that the work station stops in the back end, in order to avoid in the cutting process is in the process of failure and suddenly stops the tool damage and affects the processing work piece surface smooth finish.

H) each circuit has automatic air circuit breaker for short circuit protection and overload protection.

3, Longmen planer electrical control scheme

4. Frequency conversion speed control and PLC control

Table movement

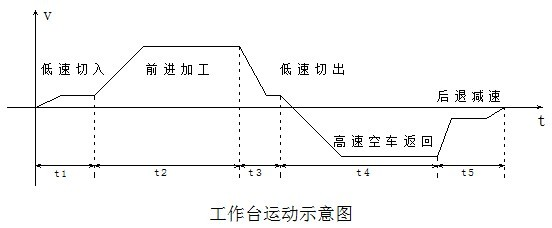

Planer of electric drive technology - double housing planer is a frequent reciprocating motion of the production machinery and its work cycle. Advance process is the cutting stroke, back without cutting, so that the stage for the next step to prepare for cutting.

As shown in the figure of Longmen planer table automatically, is divided into six sections:

Period T1 said planing bench starting, knife to cut into the workpiece stage, in order to reduce tool just cut into the workpiece moment, tool is subjected to the impact and prevent the workpiece is collapsing and the speed is low. Frequency: 10Hz

The T2 section is the plane cut, and the speed is accelerated to normal speed, frequency: 40Hz.

The T3 section is planing to prevent from workpiece, edge crack, also requires low speed. Frequency: 10Hz.

T4 section for the return, return process, planer tool is cutting a workpiece, in order to save time, improve processing efficiency, return speed should be as high as possible some. Frequency: 120Hz.

T5 segment as buffer. Return stroke is about to end, and then reverse to the working speed, to reduce the impact on the transmission machinery, the speed should be reduced, after entering the next cycle. Frequency: 10Hz.

Working table speed regulation requirements

(1) low speed area

Table movement speed is low, the cutting force is determined by the motor cutter allows maximum torque. After the motor is determined, the maximum cutting force is determined at low speed. Therefore, the motor is the constant torque output in the low speed machining area.

(2) high speed area

When the speed is high, the cutting force is limited by the strength of the mechanical structure, the maximum cutting force is inversely proportional to the speed, so the motor is the constant power output.

Frequency converter and PLC selection

Frequency converter selection: ECF200-075G3 + +9 BU20-3-075 European 22KW resistance box;

PLC choice: DVP60ES2OOR + DVP16XP2OOR comes with RS485 communication port, convenient and inverter communication, change the parameter settings;

Text selection: TPO4G-BL-CU

5, B2010A Longmen planer electrical control transformation

The programmable logic controller (PLC) and ECF200 converter implementation of planer automatic control and stepless speed regulation, eliminate the reversing impact, improve work efficiency, reduce noise, banned the original control system, so as to achieve both economic and fast running planer. After the transformation, the electrical control system is simple, clear, easy to maintain.