light industry

yichuangfei The application of 500M in the numerical control punch press

2016-05-12

First, the foreword

Punch press is mainly for sheet metal forming. Through the mold, can make the punching, forming, stretching, dressing, precision punching, riveting and extrusion parts, etc., are widely used in electronics, communications, home appliances, transportation and other fields.

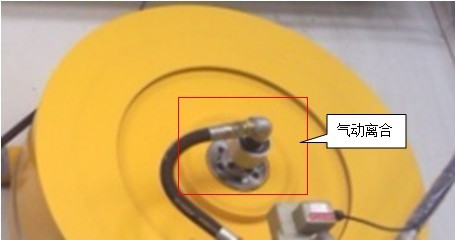

The punch is the circular motion into linear motion, by the main motor output, driven by the flywheel, driven by the clutch gear, crankshaft (or eccentric gear), connecting rod and so on, to achieve the linear motion of the mold.

Two, the characteristics of the punch press control

1 dead problem of crank and connecting rod

Punch presses are usually the crank connecting rod mechanism of the rotary motion into reciprocating motion, and crank and connecting rod mechanism is dead ("dead", and "dead"), the whole motion cycle and load changes is not uniform, showing periodic fluctuations.

2, stamping work when the mutation load problem

Punch basically has at least three operating points, with the load and the nature of the mutations: (1) over the upper dead point; (2) across the bottom dead center; (3) is in contact with workpiece stamping.

3, part of the workpiece stamping, the problem of low speed operation

Automatic continuous punching machine, the mechanical hand in material feeding, nature is more rapid and better. In some cases, it is required that the punch press has good low speed characteristics.

4, in the adjustment of the mold, the problem of moving

Punch in the adjustment of the mold, the need to move. Also is clutch will continue to pull off, this will cause motor very frequent loading and unloading, when requested frequency converter has good current suppression.

Three, ECF500M in the numerical control punch on the advantage of the application

1, the real current vector control technology, perfect low frequency torque

Rely on years of technology accumulation, Wei Chuang electrical has a very mature current vector control technology. The vector is the significance of the stator current through the coordinate transformation, decoupled into the excitation current and torque current, so that the two components can be adjusted independently, so as to facilitate the adjustment of the load.

2, fast and stable speed tracking and then start function

For the operator, it is often directly off the inverter power supply, this time the motor is in a state of free stop. The operator then joined the power supply, once again on the motor to start, this time the inverter needs to quickly track the speed of the motor, and stable operation. yichuangfei ECF500M tracking the time required is less than 2S, the fastest 500ms.

3, protection of the inverter and motor current limit function

Because the use of vector control technology, therefore, makes the torque current of the motor is easy to control, under normal circumstances, Wilson hit fly ECF500M is 200% of the torque current limit. When debugging punch can be based on the maximum load were observed maximum working current of the inverter, appropriate to join the current restriction, so when the load torque due to mechanical causes jamming, frequency remained at the limitations of current values without burning motor to the motor protection.

4, perfect voltage suppression function

As the punch is to do with the slider, the next cycle of movement. When the slider downwards, in some specific motor is in the state of power, this time the need for frequency converter of motor feedback voltage to make Yi Chuang Fei converter can make the inhibition of voltage within 2ms.

Five, the end of the language

After the customer actual experience, to Yi Chuang Fei ECF500M in CNC punch press reflected the performance and stability are given a high evaluation.