light industry

Application of ECF300 series inverter in the machine

2016-04-29

一、preface

In the field of construction industry, domestic common wall materials can be divided into two categories, namely solid clay brick and new wall materials. With clay as the main material by sintering process made of solid clay brick (commonly known as red brick), because of its simple process equipment, a long history of use, for a long time are the main wall materials; to cement, sand and fly ash, coal gangue, slag and other industrial waste or construction waste as the main material by mixing, vibrating and pressing processes made of non clay brick, building block and other new wall materials, similar to the new wall materials in recent decades in China by the gradual popularization. The concrete block is most commonly used. "Prohibition" is the prohibition of the use, sale and production of solid clay brick. Compared with the new wall materials, solid clay brick in the process of making existing excavation destroys field, energy waste, environmental pollution and other unfavorable factors, so the state has adopted a number of hard targets and policies to encourage the use of new wall materials, progressively disabling solid clay brick. According to the relevant provisions of the state, 2010 after all domestic cities (towns) will disable all clay brick, the new wall materials provide a huge market space.

二、This machine (new wall materials)

According to different process, can be divided into press machine and two kinds of block forming machine. The high pressure extrusion will brick shaped brick (block) collectively referred to press; by vibration extrusion shaping brick (block) brick are collectively referred to as the building block forming machine. Among them, block molding machine, a high degree of automation, production block (brick) has many kinds, high yield, in the machine in the dominant position, the most widely used. ("brick" refers to the block forming machine)

1, block molding machine vibration technology

A full automatic block forming machine mainly by belt conveyor, vibration molding machine (host), feeding machine, a machine, stacking machine, control cabinet, hydraulic pump station and other components, the vibration forming device is the core part of the block forming machine, its performance directly determines the machine itself and the block forming the pros and cons.

The block molding machine depends on the vibration and pressure to make the concrete mixture in the mold box forming and compacting, so the choice of vibration parameters is very important to the performance of the block. Vibration parameters include vibration frequency, vibration amplitude and vibration acceleration, etc.. From the perspective of concrete vibration technology, the optimum vibration frequency and amplitude are different for different materials. The vibration frequency should be as close as possible to the natural frequency of aggregate in the material, so that it can produce resonance, at this time, the attenuation is the smallest, and the amplitude is the largest. Block of concrete mixture aggregate diameter 3 ~ 10mm, the ideal vibration frequency is 100 to 125Hz but for building block forming machine are not up to such a high vibration frequency, which is mainly considered the vibration system especially the service life of the bearing. The vibration parameters of building block molding machine are as follows: vibration frequency range 45 ~ 55Hz; amplitude 1 ~ 2.2mm; vibration acceleration 10 ~ 18G.

2, block molding machine classification

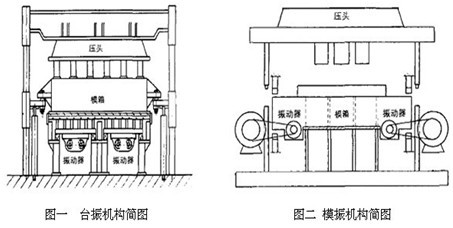

According to the different position of the vibration source, the block forming machine can be divided into a table vibration machine and a vibrating machine. The vibration source directly acts on the vibration table type to call the stage vibration machine, the model to "QT" the beginning. Vibration source installed in the mode of the model known as the mode of vibration machine, model to "QM" at the beginning. Because of Taiwan vibration machine has the advantages of large output and smaller average block vibration loss power, has become the mainstream model in domestic machine manufacturers. Figure 1, figure two respectively for Taiwan vibration and vibration mechanism of mold. Taiwan vibration machine as an example, the vibrator is usually is driven by electric motors or hydraulic motor, through two vibrators with the eccentric shaft opposite produces high-speed rotation, horizontal centrifugal force offset each other, perpendicular to the direction of the centrifugal force superimposed on each other, resulting in vertical direction vibration. When the forming block is less, a vibration source can be arranged under the mold box, and two or more vibration sources can be provided when the forming block is more.

3, the shortcomings of current electric vibrator:

(1) frequent direct start (4 to 3 times per minute), the starting current large (7 ~ 5 times the rated current), motor Wen Shenggao (70 degrees Celsius), the bearing grease is easy to melt and cause damage to the motor;

(2) the contactor moves frequently, through the current is big, the contact point is easy to aging;

(3) when the power network voltage is low, it is difficult to start the motor with load;

(4) every time you start the motor running time is 2 ~ 4S, the average power factor of low loss, serious loss;

(5) when the motor is directly started, the mechanical impact is large, and the requirement of the mechanical parts is high.

4, frequency converter frequency modulation vibration technology

How to adjust the vibration frequency, vibration excitation has been concern for brick manufacturers. Since the frequency conversion technology is widely used, a frequency converter adjusting speed regulating motor to drive the vibrator vibration forming method is many of the brick machine manufacturers pay attention to. Brick can be according to the classification of products preset different vibration frequency and vibration acceleration, start, acceleration, deceleration and stop control flexible, greatly enhance the product forming quality and performance. The following table is the technical requirements of the frequency converter for vibration molding system:

In terms of frequency converter, the difficulty of the above mentioned technical requirements is mainly in the control of acceleration and deceleration time. The acceleration time is too short, the starting current will surge, the influence of motor temperature rise; deceleration time is too short, the motor is often in the power generation state, electric energy feedback will cause the frequency converter to alarm. On the contrary, increasing the deceleration time will reduce the production efficiency of the block forming machine.

|

启动时间 |

0.3s~0.5s |

减速时间 |

1s~1.5s |

|

启动电流 |

小于1.5倍电机额定电流 |

电机温升 |

小于70摄氏度 |

|

控制方式 |

端子启停控制 |

调频方式 |

多段速调频 |

|

通讯功能 |

可与上位机通讯 |

|

|

三、Application of ECF300 inverter in the machine

My company technical staff after the scene debugging, according to the motion characteristics of the vibration system, the inverter ECF300 successfully applied to a machinery company in Guangdong, the company is a professional manufacturer of block forming machine, the table is in the use of the production data between before and after the inverter ECF300:

|

配套设备

比较内容 |

砌块成型机型号:QT6 |

混凝土砌块型号:241*116*90 |

|

变频器型号:ECF300-T3-11G两台 |

电机型号:2台7.5kW电机 |

|

|

改造前数据 |

改造后数据 |

|

|

平均每班产量 |

1220模 |

1400模 |

|

电机平均启动电流 |

130A |

50A |

|

电机表面温升 |

75摄氏度 |

50摄氏度 |

|

振动频率 |

50Hz |

58Hz |

|

砌块表面粗糙度 |

粗糙 |

平整 |

四、Advantages of frequency converter frequency modulation vibration

From the above data can be clearly seen, compared with the direct drive motor, in the vibration system using frequency converter technology has obvious advantages:

(1) can easily realize the frequency modulation of vibration system, to meet the requirements of the production process;

(2) with the reduction of speed, saving time, increasing production capacity;

(3) the starting current is small, less impact on the power grid;

(4) motor smooth start, small mechanical shock;

(5) the motor temperature rise is low, it is beneficial to the long-term stable operation of the motor;

(6) energy transfer efficiency is high, energy saving;

(7) the forming density of masonry is good, and the surface is smooth and beautiful;

(8) the frequency converter's unique AVR function, even in the case of low power grid voltage, still can output enough voltage to drive the motor to do the work.

五、Application prospect of frequency converter in block forming machine

It can be said that most domestic manufacturers of brick of converter frequency of vibration technology are not strange, but out of consideration of cost and reliability of the technology, most manufacturers have failed to make the the technology of mass production. But along with the market competition is becoming increasingly fierce, and continuous improvement of technological requirements, seeking technical innovation, improve product performance has become the brick enterprises an important issue. It is proved that frequency converter frequency modulation vibration technology has more advantages than other vibration technology, and the market conditions are ripe, the current is the favorable opportunity to promote the application.