light industry

Special scheme for vacuum pump of ECF300 vector transducer

2016-04-29

一、preface

Vacuum pump is a rotary vacuum pump, must be used before the pump can be used. Its function is to remove the gas molecule from the vacuum chamber, reduce the gas pressure in the vacuum chamber, and make it reach the required vacuum degree. A large pumping speed over a wide pressure range, which is not sensitive to the dust and water vapor in the exhaust gas. Vacuum pump classification is extensive, mainly in the WLW series vacuum pump, W type vacuum pump, 2x type vacuum pump, ZJ type vacuum pump, 2SK type vacuum pump, SK type vacuum pump, 2BV vacuum pump, MH-2 type vacuum pump, tlz type vacuum pump, SL type roots blower and jzjx type vacuum pump, JZJS type vacuum pump, JZJWLW type vacuum pump, JZJP type vacuum pump, RPP type vacuum pump, 2XZ type vacuum pump model.

Vacuum pump is widely used in the field of plastic machinery, chemical pesticides, chemical dyes, brick machinery, low-temperature equipment, paper making machinery, chemical and pharmaceutical, food machinery, industrial electric furnace, electronic industry, vacuum equipment, fertilizer, metallurgy, petroleum, mining, ground treatment.

China's production of vacuum pump manufacturers a lot, the annual sales of all vacuum pumps around about $1 million, but only the equivalent of the annual sales of a vacuum pump in the United States Kinney company. Through the analysis of the global vacuum pump market, we can see that the market and application of various types of vacuum pumps are constantly changing and developing. China vacuum pump manufacturing industry has a long history and strong foundation, it has in various fields is applied and validated, some products are also exported, recognized by foreign users and was well received, it should be said vacuum pump in China manufacturing industry in the domestic and foreign market still has a huge space for development.

二、The control problem of the traditional vacuum pump

The load of the vacuum pump decreases with the increase of the vacuum degree. When the air resistance is big in the container, the vacuum pump often works in the overload condition, with the increase of the vacuum degree, the current drops, the motor works normally. When the container is sealed properly, motor overload work for a short period of time, will not cause burning motor things happen; when the decline in sealing container, motor in the overload condition for extended periods, there will be burning motor phenomena occur.

In order to solve the problem of pump overload, the following methods are used:

1) using mechanical automatic pressure regulating bypass valve.

The bypass valve is installed between the roots vacuum pump entrance and exit of the bypass pipe. The pressure difference between the inlet and outlet of the valve is not more than the rated value. When the pressure reaches the rated value, the valve through the pressure automatically open, make the roots vacuum pump inlet and outlet are interlinked, resorted to between the inlet pressure decreases rapidly, then roots vacuum pump with almost no difference of load pressure. When the pressure is lower than the rated value, the valve automatically shut off gas through the roots vacuum pump in the pump away. Roots vacuum pump with bypass relief valve can be started at the same time with the former pump unit, the operation is simple and convenient.

2) using hydraulic coupling

The use of hydraulic coupling can also prevent the pump overload phenomenon, so that the pump can work under high pressure. The hydraulic coupling is installed between the pump and the motor. Under normal operating conditions, the hydraulic coupling is delivered to the pump by the motor end to the rated torque. Regulated by the amount of liquid in a Roots vacuum pump maximum pressure difference is transmitted by hydraulic coupling of the maximum torque to decide, and hydraulic coupling can transfer the maximum torque. When the pump at high pressure difference work or with the pump at the same time at the same time, in the liquid coupling produced a differential speed that is sliding, only the transfer of a certain torque, so that the pump to slow down the work. With the gas, the gas load decreases, the roots vacuum pump gradually accelerated to the rated speed.

3) using the vacuum electrical components to control the pump inlet pressure

In the entrance pipe roots vacuum pump is arranged at the bellows relay or electric contact pressure gauge vacuum pressure sensitive component. After the start of the vacuum system, when the roots vacuum pump inlet pressure is lower than a given value (pump allows start-up pressure), pressure sensitive component signal according to the electric control system of Roots vacuum pumps (such as roots vacuum pump bypass pipeline is arranged in the vacuum system, and close beside the through pipe valve) opening. If the pump inlet pressure is higher than the specified value, then shut down automatically roots vacuum pump (or at the same time open the pump bypass pipeline valves), so as to ensure the reliable operation of Roots vacuum pump.

It is obvious that the above methods have complex structure, high cost, poor control precision and serious energy waste, which can not meet the requirements of equipment development.

三、Common inverter applications

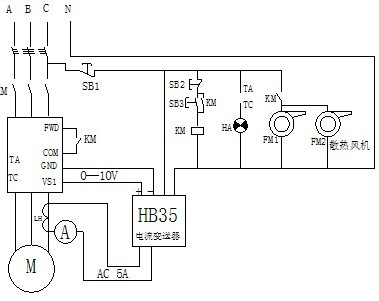

In order to protect the motor, part of the vacuum pump manufacturers the converter with the actual current of current transformer and current transmitter detection of motor, and then convert the analog signal input converter for inverter PID operation, so as to control the motor current and motor speed, finally reaching the purpose of protecting the motor.

From the left, we can see the complex control loop, although the inverter to realize current closed-loop PID control, but the control accuracy is not high and complicated transformations. Can not distinguish between motor blocking and the normal load current, may cause the motor to work for a long time in the blocking state, resulting in burning motor. Control effect is not ideal.

四、Yichuangfei ECF300 vector inverter special vacuum pump scheme

Yi Chuang Fei ECF300 vector inverter adopts the world's leading without speed sensor less vector control algorithm, the stator current according to the coordinate transform decomposition as the torque current component and the exciting current component, in order to achieve precise torque control. Compared with the V/F control algorithm, it has the advantages of good low frequency torque characteristics, good dynamic response characteristics, high speed control accuracy and so on.

Yichuangfei ECF300 vector inverter vacuum pump special scheme does not need to add any device in the external, the inverter itself can achieve precise control of motor current and speed.

Whether the container sealing performance is good or bad, ECF300 vector inverter without the need for any external auxiliary equipment can control motor current in the motor rated value within and control range can be adjusted, control precision can reach + 1%. On this basis, the vacuum pump with the highest efficiency to run, with the fastest speed to achieve the set of vacuum.

Meanwhile Yi Chuang fly ECF300 vector frequency converter can also be locked rotor current and load current for rapid identification of the vacuum pump, when the vacuum pump for mechanical reasons locked rotor to immediately identify and alarm and shutdown, prevent the failure of further expansion.

五、Concluding remarks

In summary, Yi Chong Fei ECF300 vector inverter vacuum pump special scheme not only solves the problem of control in the traditional vacuum pump, cost of eliminating the traditional mechanical anti overload protection device, and simplify the inverter control circuit, comprehensive benefit is greatly improved. In practice, the vacuum pump manufacturers have been obtained.