light industry

Special inverter power control scheme and frame line

2016-05-13

一、introduction

In the wire and cable industry, many processes are from the line to close the end of the line, the link line, how to overcome in the process of line of the wire releasing tension uneven phenomenon is many equipment design engineer and product engineer urgent to solve problems. In the past the electrical design, electrical design engineer often uses A/D, D/A module, tension control technology of PCB board PLC, to get the line speed of the demand placed by the potential reading tension rocker potentiometer, the method to keep the tension constant, because the analog signal lines signal lines generally take tension swing the rod and potentiometer emitted from the D/A module control inverter speed too easy to cause the distortion of the signals, and adjusting parameters of PID on different internal diameter take-up wheel corresponding to different PLC, such as the PID setting is not appropriate, easy to make electrical under the control of the line wheel is in an unstable state, and finally let tension in a difficult constant state, thus affecting the quality of the products.

二、technological requirements

As the front end of a variety of devices, the power line rack has a wide range of applications, in general, the requirements of the power cable rack have the following:

1, wire and cable manufacturing industry, all the processing of wire rod must be neatly rolled coil.

2, processing machinery in the start, stop, normal processing, wire line speed is changing, and the volume diameter is also changing, must ensure that the coiling machine line speed and processing machinery line speed.

3, when the roll, the roll machine must be automatic tracking processing machinery line speed, according to the automatic adjustment of the winding speed, keep and processing speed.

4, put the line speed can automatically track the lead to take speed, the line speed can automatically track processing line speed, automatic reversal of the line, break the parking protection.

5, in the winding process, keeping constant tension wire.

6, when the stable operation at a certain speed, the pendulum rod to be stable.

Yi Chuang Fei ECF100-L special inverter is currently has the only domestic inverter, excellent control performance and good reliability, but also to ensure the Yi Chuang Fei inverter wire and cable industry of superior performance.

三、Control of the line wheel and the wire winding wheel

The line wheel of on line speed depending on the take-up pulley the take-up rate, because the take-up pulley always have a start and stop deceleration, so to the line wheel a constant speed, also due to changes in wheel electric wire and cable online, in certain speed, line speed is constantly changing. Collection of line tension size has a direct influence on the product quality, excessive tension, take-up tight, for the path line deformation or rupture in the pistil, the tension is too small, take-up pulley take-up will axial sliding and dislocation, the formation of irregular line collection yielded in the winding core. All of these, this requires that the line wheel can be modified according to the balance position of the tension swing lever.

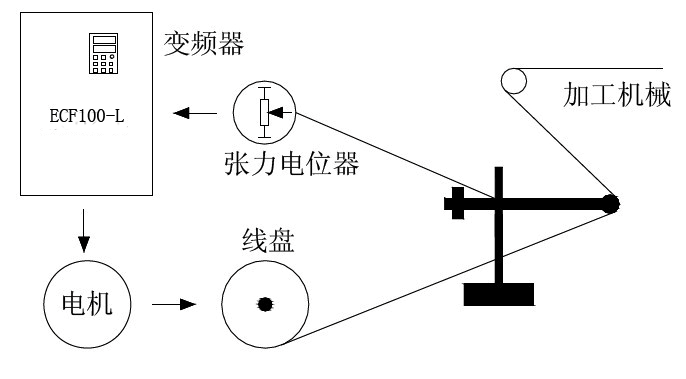

Wire frame principle diagram:

四、system configuration

1, special ECF100-L power wire inverter of a built-in brake unit, braking resistor according to motor power installation.

2, other accessories: Tension potentiometer, fixed pulley, moving pulley, stop the magnetic switch, etc..

The power wire frame diagram of the scene:

Equipment characteristics:

1, meaning the fool type power retractable cable special inverter; just wiring is correct, do not need to set the functions of the converter parameters, the boot can normal work.

2, automatic identification take-up speed and direction, automatic tracking retractable line and the line speed, tension rod basic maintenance in the midpoint of the power retractable line frame.

3, both large and small cap, both thick and thin wires, both high and low speed, constant tension.

4, as long as a winding wheel, simplify the mechanical structure, save the cost of equipment.

5, built in, the lower limit of detection function, can not travel switch.

6, equipment debugging is simple: only the correct adjustment of the tension detection potentiometer position, boot can automatically track the speed of the lead, without other external signal control, directly constitute an independent overall.

五、conclusion

Yi Chuang Fei converter ECF100-L application in cable industry actually well solves the electric wire frame and a take-up wheel of electric control in the wire and cable industry. As the wiring is simple, the inverter comes with PID and closed loop control function, eliminating the need for A/D, D/A module to convert the work and PLC programming. All this, so that an ordinary electrical maintenance personnel have to do. So yichuangfei ECF100-L is the transformation of the existing electric wire and cable industry in the original mechanical put a preferred frame line.