light industry

Application of ECF300B inverter in Shengli Oil Field

2016-05-13

一、summary

Pumping unit at present, there are many forms and common is seen on TV that with a big fan of iron that, move back and forth, image become "ketouji". However, traditional kowtow machine has big starting impact, runtime power consumption, inefficient, and many other problems, coupled with the well condition complex, often appear heavy oil, wax, Shaka phenomenon, broken rods, burning motor phenomenon also occurs frequently, and the electric motor to very good protection, once a failure occurs, a large quantity of equipment maintenance, due to many reasons above longitudinal and need to sucker rod pumping equipment transformation.

Chuangyi fly inverter ECF300B is high performance current vector inverter, with induction motor stepless speed, and on motor protection function superior, with over current protection, overload, overvoltage, undervoltage and stall, and deceleration time is adjustable, with a soft start function, starting current is rated current 1.1-1.4 times, can effectively protect electrical and mechanical equipment, motor with self learning function, the motor parameters identification and provide stability and efficiency of the motor, using our inverter and its use effect is very obvious.

二、technological process

Oil pumping unit is the exploitation of oil is a kind of machine equipment, ketouji namely beam type oil pumping machine is used extensively in oil field of the traditional oil pumping equipment, usually by the general AC asynchronous motor drive directly. The crank belt to balance weight block drives the oil pumping rod, driven underground pump and a fixed cycle of up and down reciprocating motion, the underground oil is sent to the ground. Oil pumping machine actually and we usually home oneself dozen wells pumping principle, but also through a piston rod (sucker rod) of the pumping action of the oil pump, then through the underground buried pipeline away. The only difference is that the action of the pull rod is driven by an electric motor.

1, as the pumping oil equipment, the movement is repeated to improve, with a stroke of a promotion, the power from the steel slider to the motor to drive the two considerable weight, when the slider lifting, similar to the role of leverage, will pull out the oil machine rod is fed into the wells, slider down, pumping rod was made with oil from the wellhead.

2, in slider down process, due to reduce the load, energy generated by the motor drive local cast, is bound to enter the regeneration power state, resulting in the increase of the bus voltage in the main circuit, frequent high-pressure shock will destroy the inverter main devices, including electrolytic capacitor and a power module, thus increasing brake circuit, for the regenerative voltage can timely release out, in order to ensure the equipment work under safe voltage. 18.5KW the following frequency converter has a built-in braking unit, 18.5KW above the need to purchase the braking unit.

三、Electrical configuration

General inverter power than the motor power of a file, if the motor is 18.5KW, then the inverter using ECF300B-T3-022G.

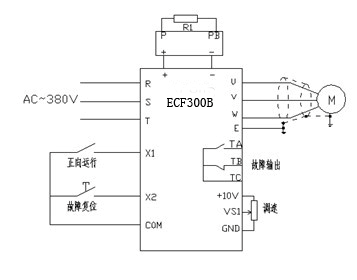

Oil pumping unit wiring diagram:

四、Parameter debugging

|

control mode |

F0.00 |

0(no PG vector control) |

|

Run command channel |

F0.02 |

1(terminal control) |

|

Frequency channel |

F0.03 |

2(potentiometer given VS1) |

|

Acceleration time 1 |

F0.14 |

According to the actual situation of the scene set |

|

Deceleration time 1 |

F0.15 |

According to the actual situation of the scene set |

|

Multi function terminal X1 |

F2.00 |

1(forward run) |

|

Multi function terminal X2 |

F2.01 |

8(fault reset) |

|

relay(TA/TB/TC) |

F2.31 |

3(fault output) |

五、Transformation efficiency

(1) improve the power factor, reduce the power supply current, the quality of the power grid is improved.

(2) energy saving. In sufficient amount of oil can be frequency is set to be larger than the rated speed of the motor, and greatly improve the production efficiency, less oil, appropriate to reduce the speed and reduce stroke and yield have to be ensured and power consumption is reduced.

(3) converter has the soft start function, sucker rod pumping system is to avoid excessive mechanical shock, prolong the service life of the equipment.

(4) ECF300B is a high performance current vector, the real current decoupling, with all aspects of the protection function: over current, over voltage, overload, etc..