ECF100Q series inverter

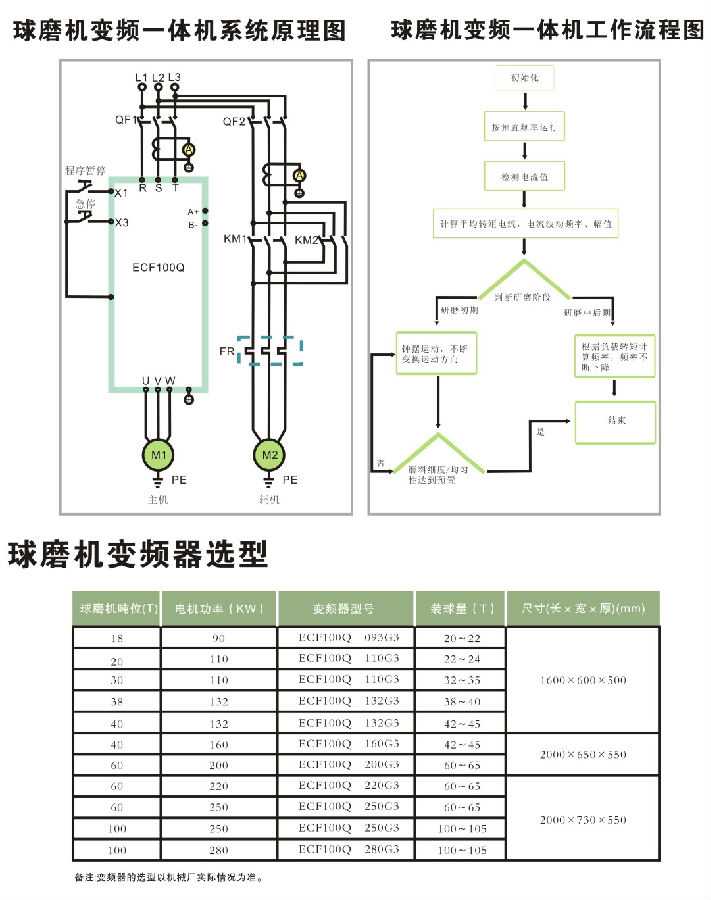

ECF100Q series ball mill is one of the frequency conversion machine developed by our company dedicated to the ball mill energy saving drive inverter, it has achieved good economic benefits for customers.

To build a conservation minded society and to reduce environmental pollution is of great economic and social significance.

Voltage level

380V (three phase power) 93KW ~ 280KW

- Product features

- Application occasions

- Data download

The main and auxiliary integrated structure design, low noise, low temperature rise, large starting torque, complete monitoring instrument.

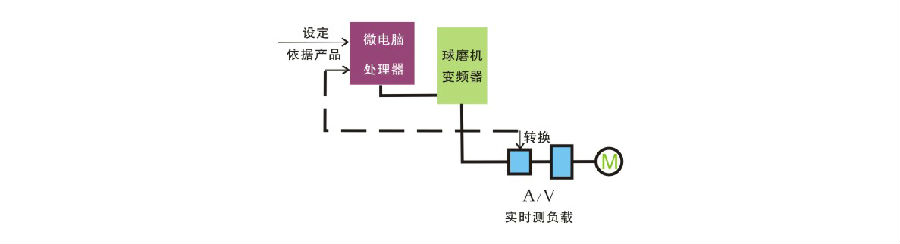

2 the use of independent innovation technology and microcomputer digital control technology through its built-in power-saving optimization control program, running state real-time monitoring of the ball mill, according to the stator current instantaneous AC asynchronous motor stator current feedback value of the ball mill, ball mill motor stator current calculation of the average torque and current fluctuation frequency, amplitude, through the synchronous rotating according to the coordinates of the field oriented vector transformation, get the current torque and current fluctuation amplitude and frequency adjustment, calculate the output power of the motor and the ball mill speed real-time optimal speed, thus changing the existing constant speed ball mill operation mode, the average speed is lower than the existing ball mill speed, achieving the purpose of saving energy, the built-in DC reactor. The power factor can be increased to more than 0.97.

3. Has a unique dynamic power saving function, energy-saving effect of more than 12% - 20%; if with elastic couplings replace hydraulic coupler, energy-saving effect of up to L 3% - 25% above.

4. Start the mill starting current control in less than 2 times the rated current of ball mill, start with excellent performance, will not cause sharp decline in power fluctuations and voltage transient, eliminate the tripping fault electric which is caused by startup, stop production phenomenon.

5 to improve the efficiency of the use of transformer capacity 20%, can save a lot of transformer capacity increase.

6. With Chinese LCD humanized interface, real-time monitoring of the host output current, voltage, frequency, main auxiliary equipment operation status, set of ball milling time, automatically shutdown, very easy to manage.

7 have perfect ball mill protection function. There are over current, over voltage, overload, under voltage, lack of phase, short circuit and other protection.

8 high rate of return, all the investment can be recovered by electricity savings. At the same time, the ball mill of the various components and motor maintenance rate decreased, the maintenance cost is reduced, labor cost reduction, service life increased by K=, the investment benefit period is prolonged, and gain the benefits.